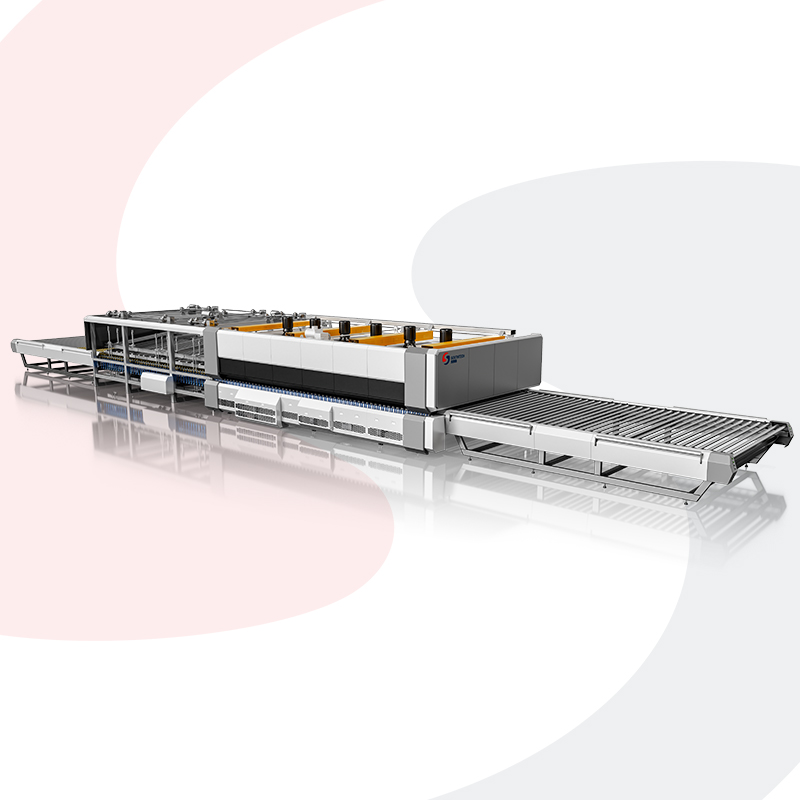

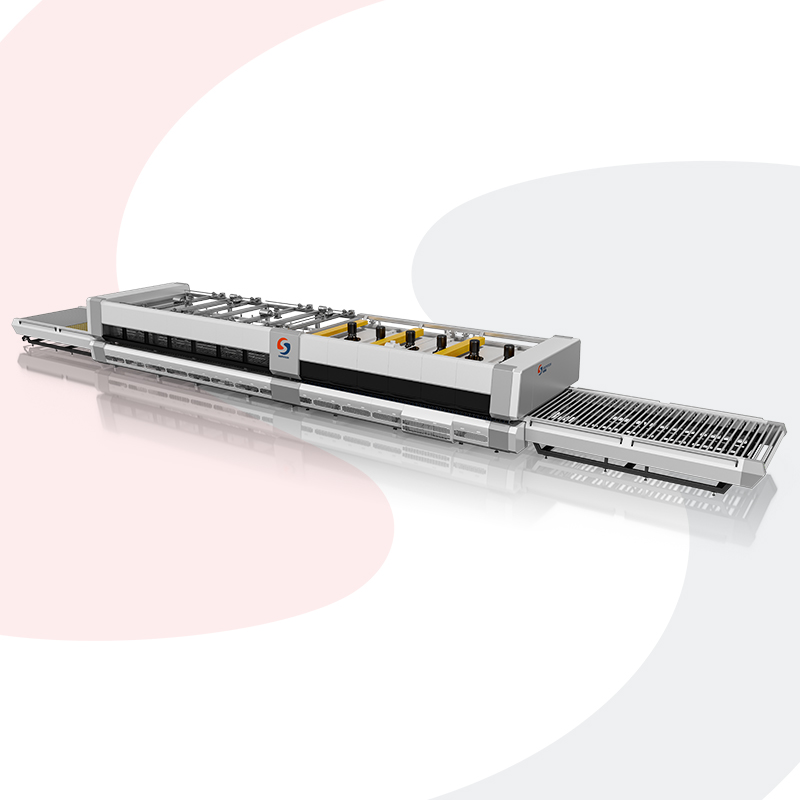

FLAT GLASS TEMPERING MACHINE WITH FORCED CONVECTION SYSTEM

Category: Coated glass、Clear Float Glass, Tinted Glass, LOW-E Glass.

- 4000mm×1000mm

- 8000mm×3600mm

- 300mm×100mm

- 2.85~19mm

Details

FLAT GLASS TEMPERING MACHINE WITH FORCED CONVECTION SYSTEM

SOUTHTECH forced convection glass flat tempering machine supports offline tempered Low-E glass, ensuring superior energy-saving performance of the finished product and meeting the market's demand for high-quality tempered glass.

The stable and reliable operating characteristics of this glass tempering machine enable consistent high-quality output in mass production, providing users with solid production guarantees and helping enterprises achieve higher quality tempered glass production and sustainable development.

Recommended Model

|

Model |

Maximum Loading Area |

Minimum Glass Size |

Glass Thickness |

|---|---|---|---|

| PG6028-H | 6000×2800mm | 350×350mm | 5~19mm |

| PG7028-H | 7000×2800mm | 350×350mm | 5~19mm |

| PG7030-H | 7000×3000mm | 350×350mm | 5~19mm |

| PG6028-2S-H | 6000×2800mm | 350×350mm | 5~19mm |

| PG7028-2S-H | 7000×2800mm | 350×350mm | 5~19mm |

| PG7030-2S-H | 7000×3000mm | 350×350mm | 5~19mm |

➤ Loading and unloading tables

Southtech Tempering Machine Loading and Unloading Tables feature custom-engineered steel frame structures that deliver robust load-bearing performance throughout glass handling processes. The conveying system integrates innovative rubber and rope roller combinations, with durable wear-resistant rubber coatings minimizing surface abrasion risks while maintaining optimal compression resistance and low friction characteristics.

Seamlessly synchronized with the tempering machine control system, the modules enable precise adjustment of step intervals, conveying speeds, and feeding intervals to accommodate various glass specifications. Integrated with sensitive glass detection sensors, the system ensures smooth material transitions through real-time signal feedback, significantly enhancing production line automation and operational efficiency.

➤ Heating system

Southtech Tempering Machine integrates advanced thermal engineering to deliver precision glass tempering solutions. Its core heating module features a split upper and lower chamber design, lined with high-performance insulating materials that effectively minimize thermal loss. Both ends of the chamber are sealed with heat-resistant pneumatic doors, ensuring airtight integrity for stable temperature regulation.

The machine employs high-temperature resistant ceramic rollers to convey glass panels, engineered to withstand prolonged exposure to extreme heat during tempering processes. Its innovative Heating system utilizes an open-matrix layout with evenly distributed heating elements across both upper and lower chambers. This configuration outperforms conventional radiant panel heating through enhanced temperature uniformity, accelerated heating rates, and streamlined maintenance access.

Constructed with corrosion-resistant inner liners and scientifically layered insulation featuring a six-surface polishing process, the chamber achieves exceptional thermal retention capabilities. This design optimizes energy efficiency while maintaining safe exterior temperatures. For enhanced serviceability, the upper chamber incorporates electric screw-lift mechanisms, enabling full-height accessibility for thorough equipment inspection and swift troubleshooting.

➤ Flat cooling system

Southtech Tempering Machine excels in its innovative Flat Cooling System design. The frame structure combines aluminum profiles and steel plates using cold riveting technology, avoiding distortion risks from thermal welding and ensuring precise flatness across the entire air grid. Equipped with nationally patented micro-jet nozzles and a clustered aperture array, the system generates a continuous high-performance cooling airflow. This patented configuration delivers uniform glass cooling with enhanced heat transfer efficiency while minimizing flow patterns, establishing a reliable cooling benchmark for premium tempered glass production.

➤ Electric control system

Southtech Tempering Machine's Electric Control System integrates intelligent parameter memory technology, expertly capturing critical processing specifications including glass thickness, dimensions, color classification, and specialized parameters for diverse float glass variations. When producing new glass configurations, operators simply input relevant process criteria - the system autonomously archives these parameters. For recurring production of identical glass specifications, technicians can instantaneously retrieve stored profiles to activate predefined operational protocols. This intelligent memory architecture streamlines workflow reactivation, eliminates redundant parameter configuration, and enhances production throughput by 23-35% across standardized batches.

➤ Convection system

As a critical process component of the Southtech glass tempering machine, the forced convection system adopts an upper/lower furnace configuration that drives high-efficiency thermal transfer during heating. The air compressor-driven high-pressure airflow precisely channels thermal energy from heating elements to glass surfaces, complemented by helical vacuum emission technology to optimize heat utilization. When processing in-line LOW-E glass, the system maintains tempering strength while minimizing energy loss. Compared to equivalent solutions, Southtech's core module demonstrates superior energy efficiency with measurable reductions in power consumption and simultaneous productivity gains, achieving uncompromised tempering quality.

➤ Unattended Automatic Heating Function

Southtech Tempering Machine's unmanned automatic reheating function optimizes production continuity. Upon completing daily operations, the equipment enters standby mode with natural temperature dissipation at 15°C per hour while maintaining continuous low-speed roller conveyor operation, ensuring persistent availability of the glass pathway. The system automatically initiates a reheating process 30 minutes prior to scheduled production periods, achieving precise temperature recovery from standby status to required process specifications. This intelligent time-sequence control eliminates preparatory downtime and direct energy consumption, providing reliable support for continuous glass tempering operations.