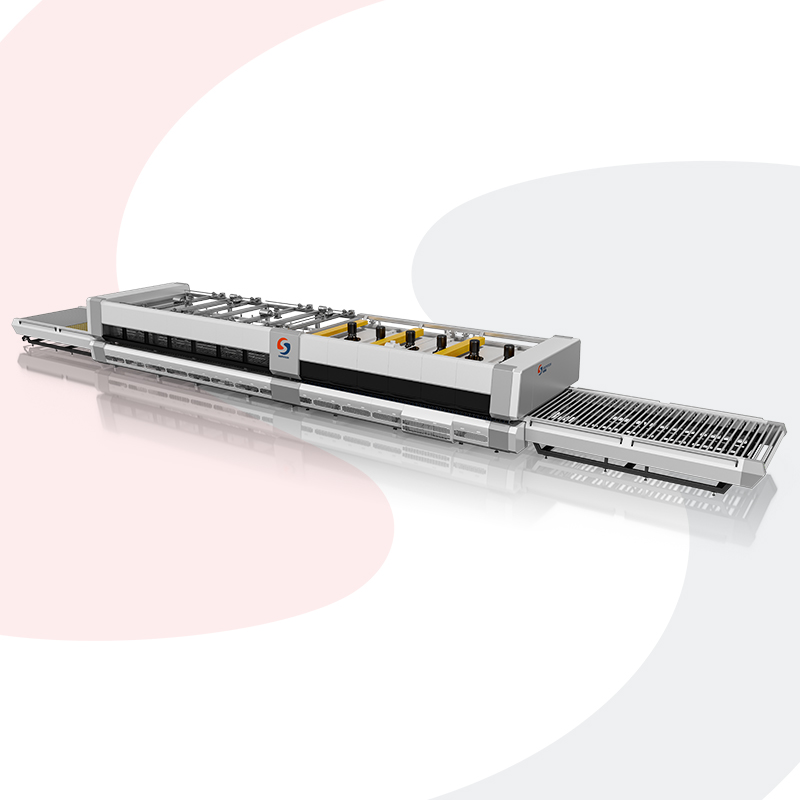

Southtech Double Chamber Intelligent Flat Glass Tempering Furnace By ZLHZ Glass

Southtech Double Chamber Intelligent Flat Glass Tempering Furnace By ZLHZ Glass

As the demand for high-end curtain wall glass in the construction industry continues to rise, Southtech has made targeted efforts to tailor a double chamber intelligent flat glass tempering furnace for ZLHZ Glass. With its excellent performance, wide applicability and advanced technical configuration, this equipment has become the core support for ZLHZ to produce high-end curtain wall glass, providing a reliable guarantee for its breakthrough in the high-end market.

In terms of size and thickness processing, this glass tempering furnace shows extremely strong flexibility. Its maximum loading area can reach 5000mmx2800mm, which can easily cope with the production of conventional large curtain wall glass; and the dual-chamber interconnection function can achieve ultra-large size processing of 12000mmx2800mm (starting from 8mm thickness). This advantage is undoubtedly the key competitiveness for high-end construction projects that pursue an integrated visual effect. At the same time, it also takes into account small size requirements and can process glass as small as 300mmx300mm. Whether it is the overall curtain wall of a large building or the local glass of a small decoration, it can be accurately adapted.

The thickness processing range is also wide, covering a range of 4.8~19mm, which can not only meet the demand for thin curtain walls that pursue lightness and transparency, but also support the production of thick glass that focuses on durability, and fully match the diverse requirements of curtain wall performance in different architectural scenes.

In terms of glass type processing, the compatibility of this glass tempering furnace further highlights its advantages. It can accurately temper temperable coated glass, transparent float glass, rolled glass, body tinted float glass, and single silver, double silver, triple silver LOW-E glass and other categories.

The powerful processing capacity is supported by a number of core technologies equipped in the equipment. The independent lifting function of the wind grille is a highlight, which can accurately adjust the distance between the wind grille and the glass according to the thickness and size of the glass. Glass of different thicknesses has different requirements for cooling intensity. Through height adjustment, every inch of glass can obtain uniform and moderate cooling air, which not only greatly improves the tempering quality of glass of different thicknesses, but also effectively improves the yield rate, providing a basic guarantee for stable production.

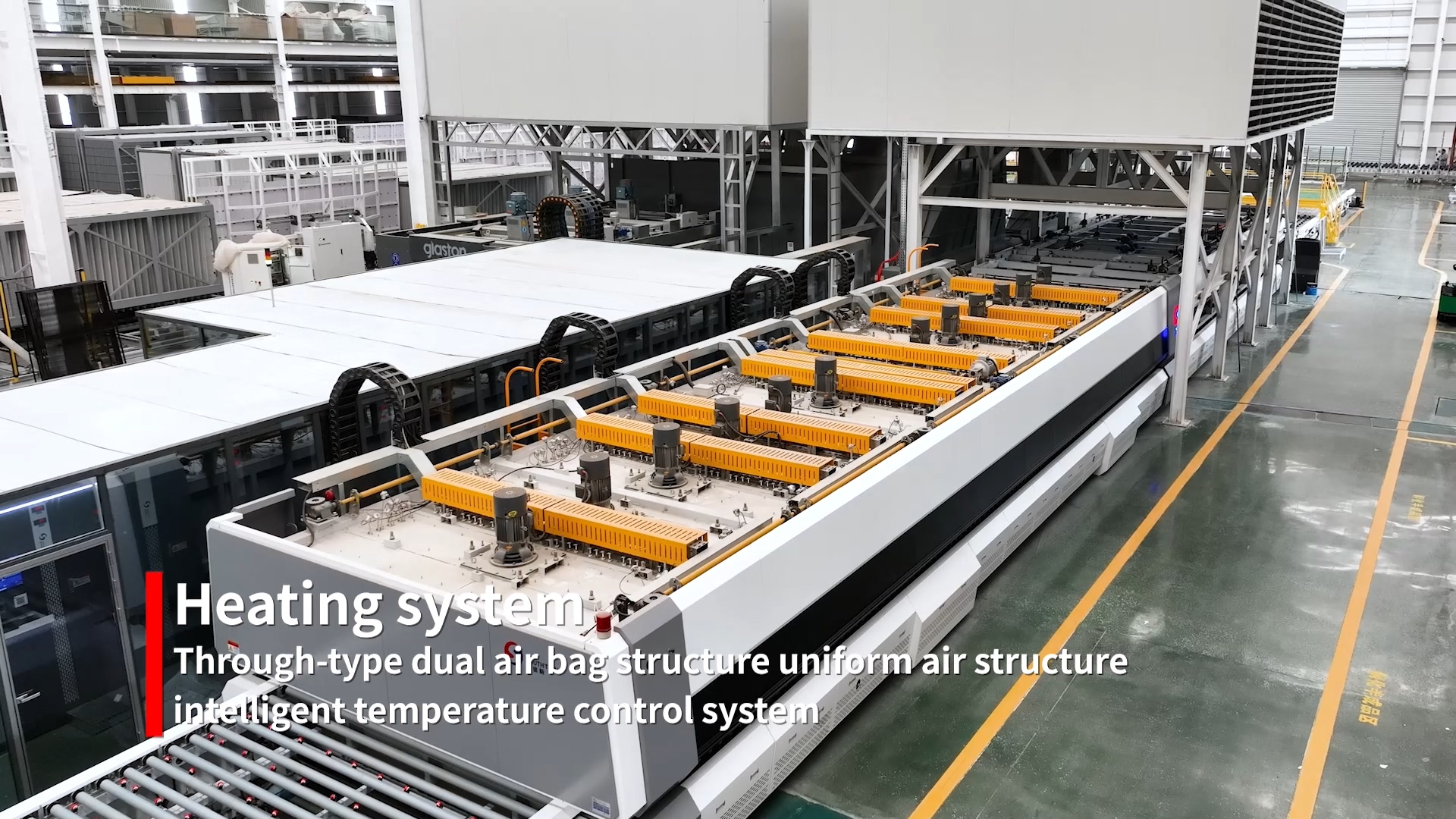

The dual-chamber dual-convection technology injects high efficiency and precision into the glass heating process. The two furnace chambers each form an independent and efficient convection circulation system, making the temperature distribution in the furnace more uniform and stable. When the glass enters the furnace body, the thermal radiation can quickly and comprehensively heat the surface and interior of the glass, avoiding the deformation problem caused by local temperature differences from the root. This is especially important for large-area curtain wall glass of 12000mmx2800mm, which can ensure its flatness. At the same time, the dual convection design also speeds up the heating speed, significantly shortens the production cycle, and achieves efficient and energy-saving production efficiency.

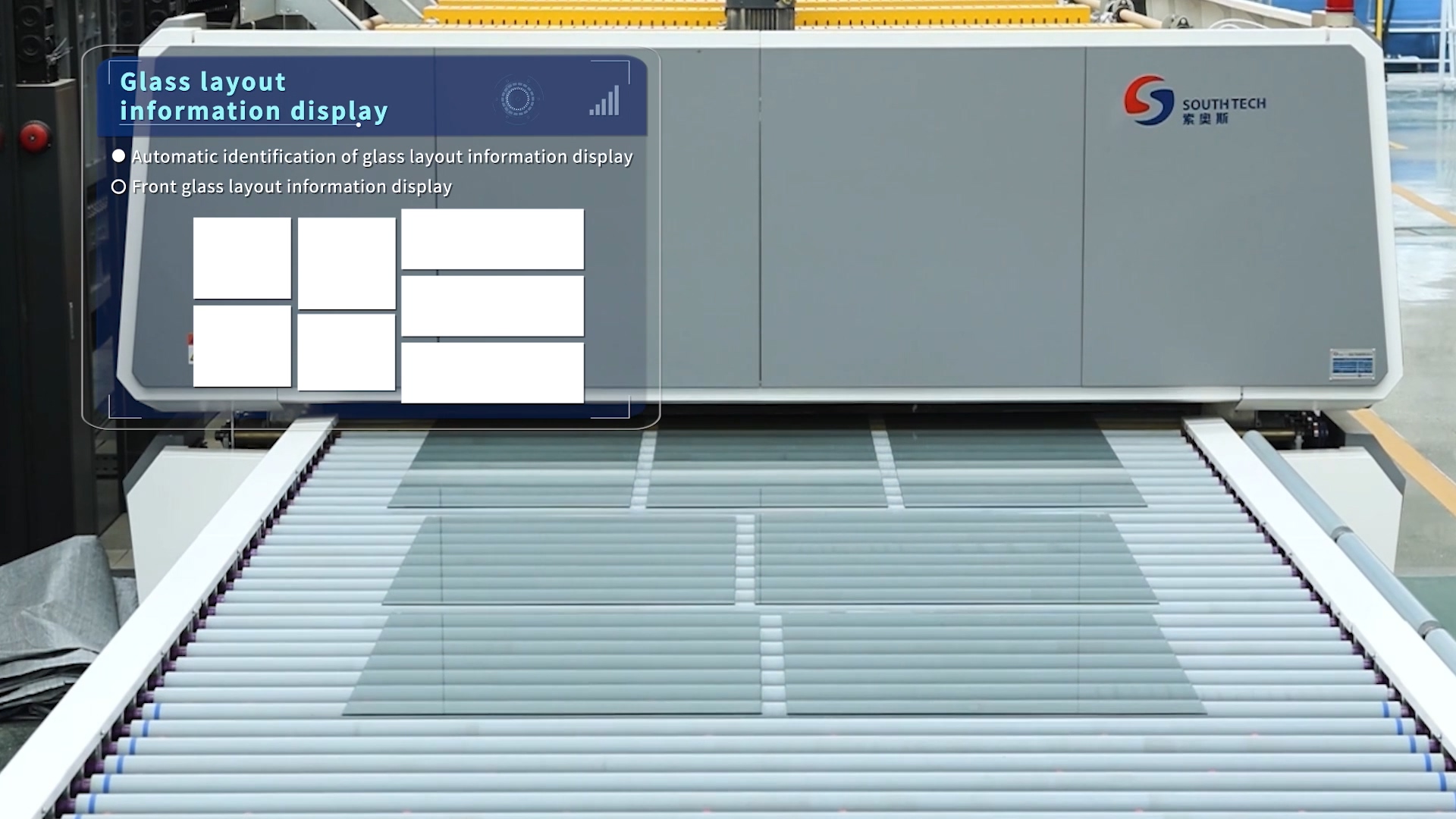

The integration of MES connection and intelligent process matching technology has brought production management into the era of intelligence. Through the real-time connection between the MES system and the equipment, production data such as processing progress and equipment operating parameters can be collected in real time, and the operator can accurately grasp the production status based on this, and realize efficient scheduling. And the intelligent process matching technology can automatically match the optimal process parameters according to the type, size, thickness and other information of the processed glass, without the need for manual repeated debugging. This not only reduces manual operation errors, but also ensures the stability and consistency of the quality of each batch of glass.

The equipment is also equipped with an IoT system, which can realize intelligent fault handling and work order management, respond to equipment problems in a timely manner and handle production work orders efficiently; it can display dynamic work orders and track them in real time, so that the production progress is clear at a glance; with the help of big data and AI-driven production optimization, production efficiency is continuously improved.

With powerful dual-chamber convection capacity, flexible size and thickness processing range, adaptability to various glass types, and advanced technical configuration, this dual-chamber intelligent glass tempering furnace customized by Southtech for ZLHZ has become the only choice for high-end curtain wall glass production. It not only helps ZLHZ achieve high efficiency and stability in production efficiency and product quality, but also promotes it to steadily move towards new heights in the field of high-end curtain wall glass, and continuously outputs more beautiful, safe and high-quality tempered glass to the market.