Heating characteristics and uniform heating treatment methods of Low-E glass

2024-12-26

Heating characteristics and uniform heating treatment methods of Low-E glass

The heating characteristic of LOW-E glass:

After the glass enters heating stove , it will swing back and forth in the stove . The upper and bottom surfaces of the glass will be heated at the same time. There are three ways for the heating transmission: conduction, convection and radiation.

In the heating process, the upper surface of glass will be heated with radiation generally. Since porcelain rollers are directly contacted with glass, the bottom furnace transfers mainly with conducting heat . The key of the glass tempering is to make the top and bottom surfaces to be evenly heated and cooled. When cooling the glass, the upper and bottom chiller will blow the glass, you can adjust the loaction of bellows damper to control the air pressure, so that the glass will not get bent. It’s easier for the top and low surfaces of ordinary glass to be heated evenly.

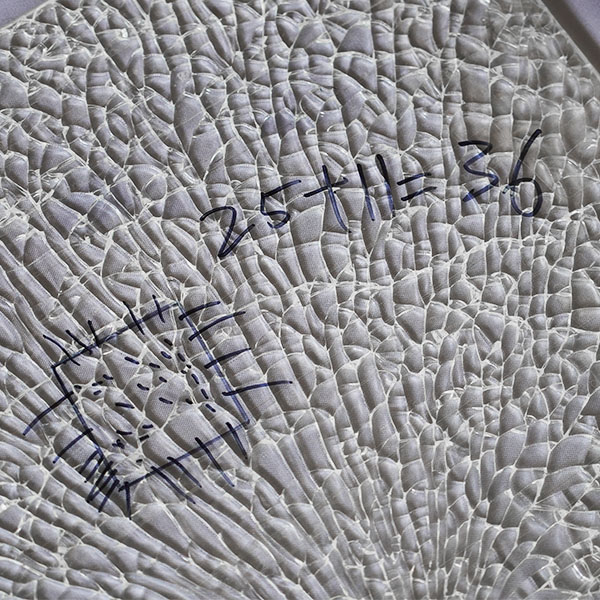

Since one of the surfaces of LOW-E glass is with a layer of special membrane, this layer of membrane has the high reflectance of infrared ray. When LOW-E glass enters the furnace (The membrane surface should be placed upwards to avoid damages caused by friction with porcelain rollers), this layer of membrane may reflect back most of the heat which is radiated by the top surface, so it’s difficult for the upper surface to gain heat. The bottom surface is heated by conduction and it can gain heat normally, so, the two surfaces will be heated unevenly. If the temperature difference is too large, the expansion quantities of the top and low surfaces will be not the same. The glass will be bent towards the upper surface which is with lower temperature, so when glass runs on the porcelain rollers, they will move in pot-shape which cause glass to be heated more unevenly. Meanwhile, there will be guide marks on the surface of the glass by the rollers. If the thermal stress aroused by the difference of temperature oversteps the glass tensile strength itself, the glass will explode in the furnace.

The ways to heat LOW-E glass uniformly:

The simplest way to heat the upper and bottom surfaces of LOW-E glass evenly is to raise the temperature of the upper furnace. Since the heat-resisting ability of the membrane layer of LOW-E glass is limited, it has a heat-resisting toplimit. If the heating temperature exceeded this toplimit, membrane layer will get damaged and it will fall down(There will be mahogany burnt spots on the surface.). So, it’s not available to just raiseg the heating temperature of the top furnace.

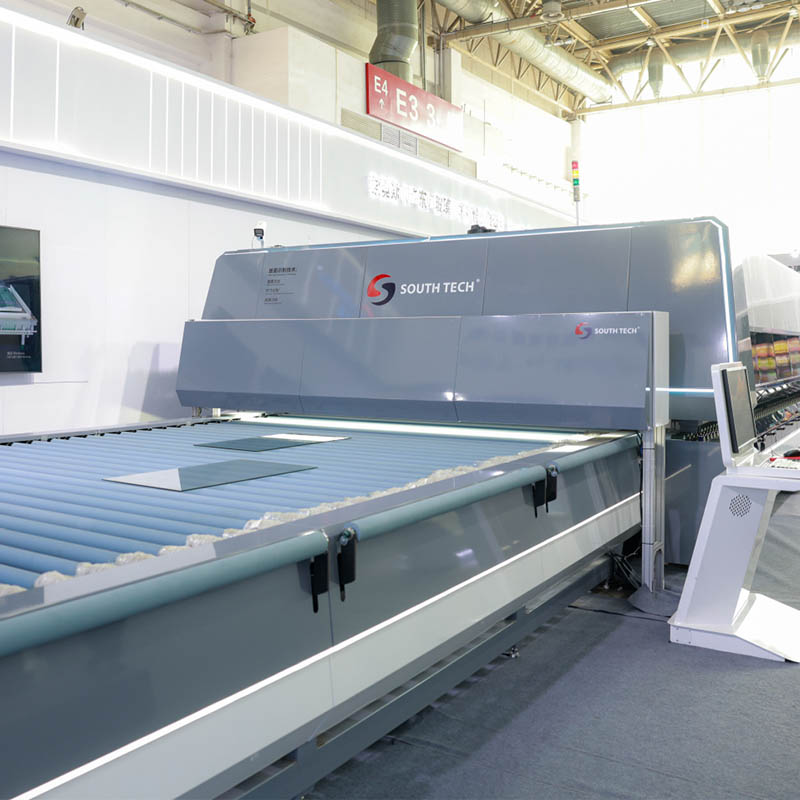

To make the LOW-E glass be heated evenly, some furnace will be equipted with a special device-- a wind mouth. It is equipted on the top of the furnace. Compressed air will be injected in the furnace through this special wind mouth. This will lead to compelling convection and forms a cycle of hot convection on the membrane surface, it will solve th problem of uneven-heating on the membrane and improve the situation of glass bending upwards. For ordinary glass tempering furnace, you may increase the wind volume of hot balance, adjust the wind volume balance of the chiller and increase the top surface pressure so as to decrease the bending and warped phenomenon.

Low-E glass,Glass Tempering Furnace,Glass Tempering Oven,Glass Tempering Furnace Brand,Small Glass Tempering Furnace