Composition and principle of glass flat bending tempering machine

2025-03-17

Composition and principle of glass flat bending tempering machine

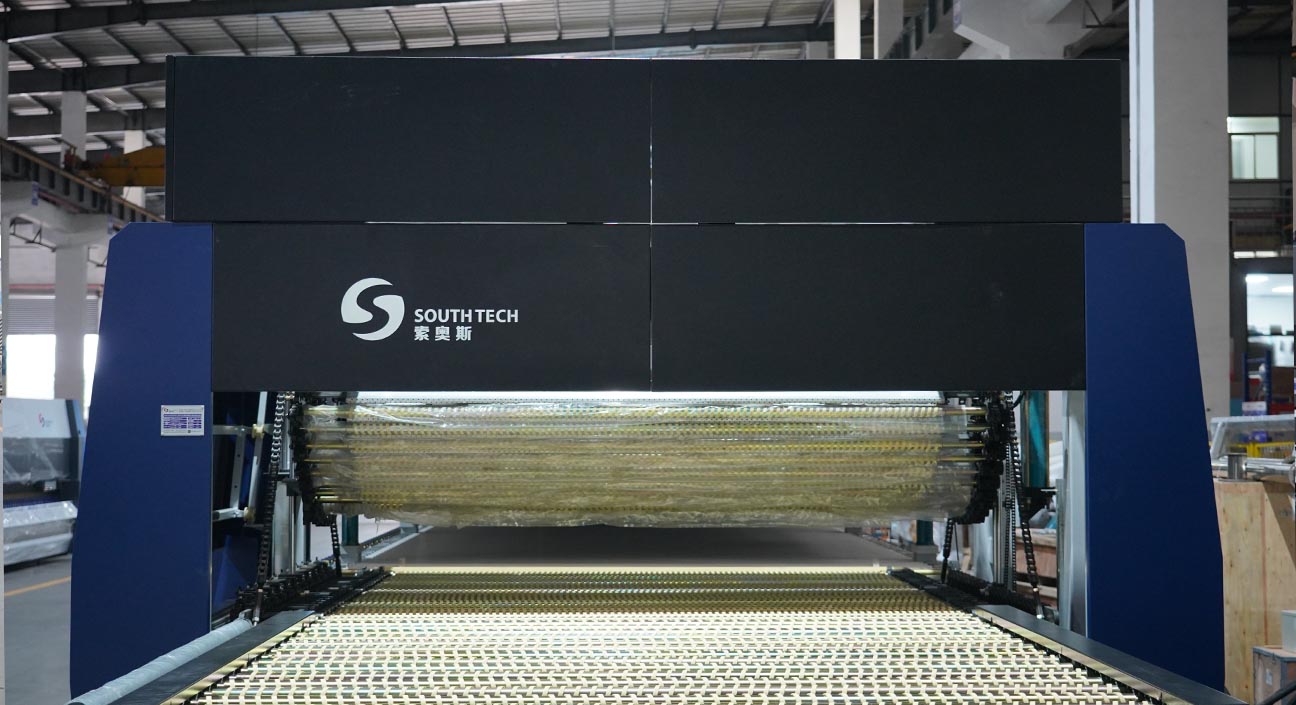

The glass flat bending tempering machine mainly consists of five parts: upper plate stage, heating furnace, bending air grille, flat air grille, and lower plate stage; In addition, auxiliary facilities such as fans, air collection boxes and ducts, electrical control systems, and computer terminals are included. The main production process of tempered glass is that the raw glass enters the glass tempering machine from the upper stage, is heated to a temperature suitable for tempering by the heating furnace body, and then enters the cooling air grille for rapid cooling tempering and air blowing cooling before entering the lower stage; If it is made of bent steel glass, it can be taken from the lower stage after entering the bending wind grille for rapid cooling and tempering, blowing and cooling. The entire process is automatically controlled by a computer, without the need for manual operation.

Loading platform function:

mainly composed of transmission rollers (rope rollers), O-rings, transmission shafts, and transmission motors. The glass is transported into the heating furnace through the loading platform roller conveyor. When producing glass, the glass needs to be placed flat on the roller conveyor, which is driven by a motor to transport the glass forward. A set of photoelectric switches is installed at one end of the loading platform near the front furnace door. When the glass is transported to this position, the switches are sensed, the rollers stop rotating, and the glass is in a waiting state for entering the furnace.

Heating furnace body function:

The heating furnace body is made of sturdy and rigid steel welded together, with a sturdy and reliable structure. The furnace body is divided into upper and lower parts, with the upper half equipped with a spiral lifting device for easy lifting during maintenance and cleaning work. The latest insulation materials are used inside the furnace body, and internationally advanced anchoring technology is applied to fix the refractory fibers. This design can not only utilize its low strength and flexibility, but also effectively slow down the transfer of heat from the high temperature zone to the low temperature zone, reduce heat loss, ensure that the heating furnace can quickly reach the required tempering temperature, and maintain a stable high temperature environment, thereby improving energy efficiency and reducing operating costs.

There is a ceramic roller conveyor inside the furnace for carrying and transporting glass, allowing it to undergo reciprocating heating inside the furnace. In addition, the upper part of the furnace body is equipped with low-power, long-life heating elements, which are assembled on ceramic tubes with spiral heating wires, and are sprayed with compressed air through specially designed convection tubes to achieve uniform heating effect (with convection). When the glass enters the heating furnace, the front furnace door opens and the upper section runs synchronously with the furnace roller conveyor, smoothly feeding the glass into the furnace; Subsequently, the furnace door is closed, and the glass moves back and forth with the roller conveyor inside the furnace within the set effective range, receiving uniform heating. After heating is completed, the rear furnace door opens and the glass is transported to the cooling air grille for further processing.

Flat air grille function:

The flat air grille is divided into two parts: quenching section (high pressure zone) and cooling section (low pressure zone). Each consists of upper and lower air grilles, and the height of the air grilles is adjusted electrically. When adjusting the air grilles in the quenching and cooling sections, the upper and lower air grilles open and close simultaneously. For the convenience of production, the lower air grilles in the quenching and cooling sections can be adjusted separately up and down. When producing glass with a thickness of less than 5mm, use a large fan to blow air in the quenching section. The glass has been tempered by slowly passing through the quenching section from the furnace body.

After finishing, enter the cooling section and use a small fan to blow air for cooling. When producing glass with a thickness of over 6mm, the glass quickly enters the cooling section from the furnace body (without starting the fan), and the rapid cooling and cooling processes of the glass are all completed in the cooling section. The upper and lower air grilles are connected in parallel with several air distribution boxes to facilitate the diffusion of hot air flow. There is a conveyor roller in the middle of the wind grille. In order to evenly cool the glass, the roller drives the glass to continuously swing during blowing.

The flat grille is divided into two main parts:

The quenching section (high pressure zone) and the cooling section (low pressure zone), each of which includes an upper grille and a lower grille. The height of the air grille can be adjusted automatically or manually. The air grille height automatic adjustment function installed in the SOOS glass tempering machine can automatically match the process parameters according to the type of glass, automatically adjust the height of the air grille, and achieve the optimal cooling and blowing effect. When adjusting the upper and lower air grilles of the quenching or cooling section, they will open and close synchronously. For the convenience of production operations, the downwind grilles of the quenching and cooling sections can be adjusted separately.

When processing glass with a thickness of 5mm or less, a large fan will be used to blow air in the quenching section. At this time, the glass will pass through the quenching section at a slower speed to complete the tempering process, and then enter the cooling section for cooling by a small fan. For glass with a thickness exceeding 6mm, it can be quickly cooled and quenched in the cooling section without the need to start the large fan in the quenching section. The entire cooling process is completed within the cooling section. The upper and lower wind grilles are composed of multiple parallel wind distribution boxes, which helps to effectively diffuse the hot air flow. There is a conveyor roller in the middle of the wind grille. In order to ensure uniform cooling of the glass, the glass will move back and forth under the drive of the roller during the blowing process.

Function of the curved air grille:

The curved air grille includes a variable arc shaped air grille, an upper pressure roller drive roller, and upper and lower air exhaust components. When producing curved steel glass, the glass is heated and sent into the curved air grille area, where the grille begins to deform according to the preset curvature. Glass relies on its own weight and naturally bends with the bending of the conveyor roller and air grille; For glass that requires deeper bending, an upper pressure roller will be used to assist in glass forming.

During the entire molding process, the glass will oscillate back and forth under the drive of the conveyor roller, ensuring that it uniformly conforms to the shape of the grille, thereby achieving precise bending molding. Subsequently, the glass is cooled by blowing air through the exhaust, which is divided into upper and lower parts, each connected to a wind collection box. The wind collection box is then connected to the fan through an air duct to provide the necessary cooling airflow. After completing the tempering process, the glass will be automatically transferred to the lower stage.

Function of the lower stage:

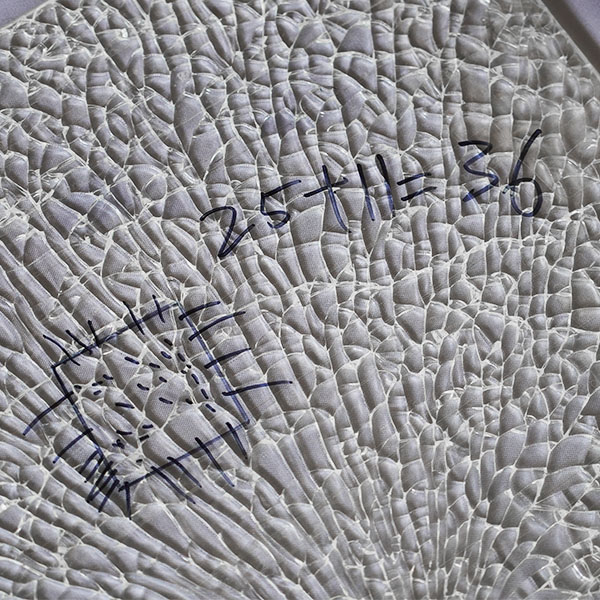

The design principle of the lower stage is the same as that of the upper stage, and it also adopts a roller type platform structure. A photoelectric switch is installed at the end of the platform. When the glass moves to this position, the photoelectric switch can sense the presence of the glass and trigger a signal to stop the roller conveyor from rotating. At this point, the staff can safely perform manual cutting operations.

As an excellent enterprise in the field of glass tempering machines in China, Southtech focuses on providing efficient and energy-saving glass deep processing solutions to customers nationwide. The company mainly manufactures and supplies glass flat tempering machines, glass bending tempering machines, glass flat bending tempering machines, continuous glass tempering machines, etc. The equipment applications cover the construction industry, furniture and home appliance industry, photovoltaic industry, tempered mirror industry, etc.

Based on 23 years of industry experience, Southtech is not only one of the standard setters for glass tempering machines in China, but also well-known in the industry for customized services. It can customize glass tempering fmachines according to customer needs to cope with different tempered glass processing; Southtech' service network covers more than 30 provinces and cities in China, and exports to multiple overseas markets such as Asia, the Middle East, Southeast Asia, and Europe and America.