The role of glass tempering furnace heating furnace body in the process of glass tempering

2025-03-06

The role of glass tempering furnace heating furnace body in the process of glass tempering

Tempered glass is widely used in modern architecture and industrial applications due to its excellent strength, durability, and safety. The manufacturing process of this material relies on a key equipment - the glass tempering furnace, especially one of its core components: the heating furnace body. This article explores the working principle of the heating furnace body in the process of glass tempering and its impact on the quality of the final tempered glass product.

1. Basic functions and technical details of the heating furnace body

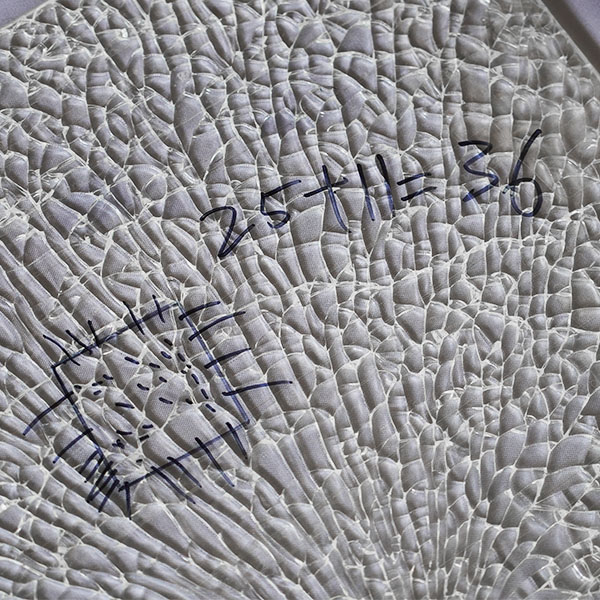

The main task of the heating furnace body is to uniformly heat the flat glass. This step is crucial to ensure that the glass can withstand the stress generated during the subsequent cooling stage. Usually, glass needs to be heated to near its softening point (approximately 600-700 ℃) in order to form sufficient compressive stress on its surface and tensile stress inside. In this way, ordinary annealed glass can be transformed into tempered glass with high impact resistance.

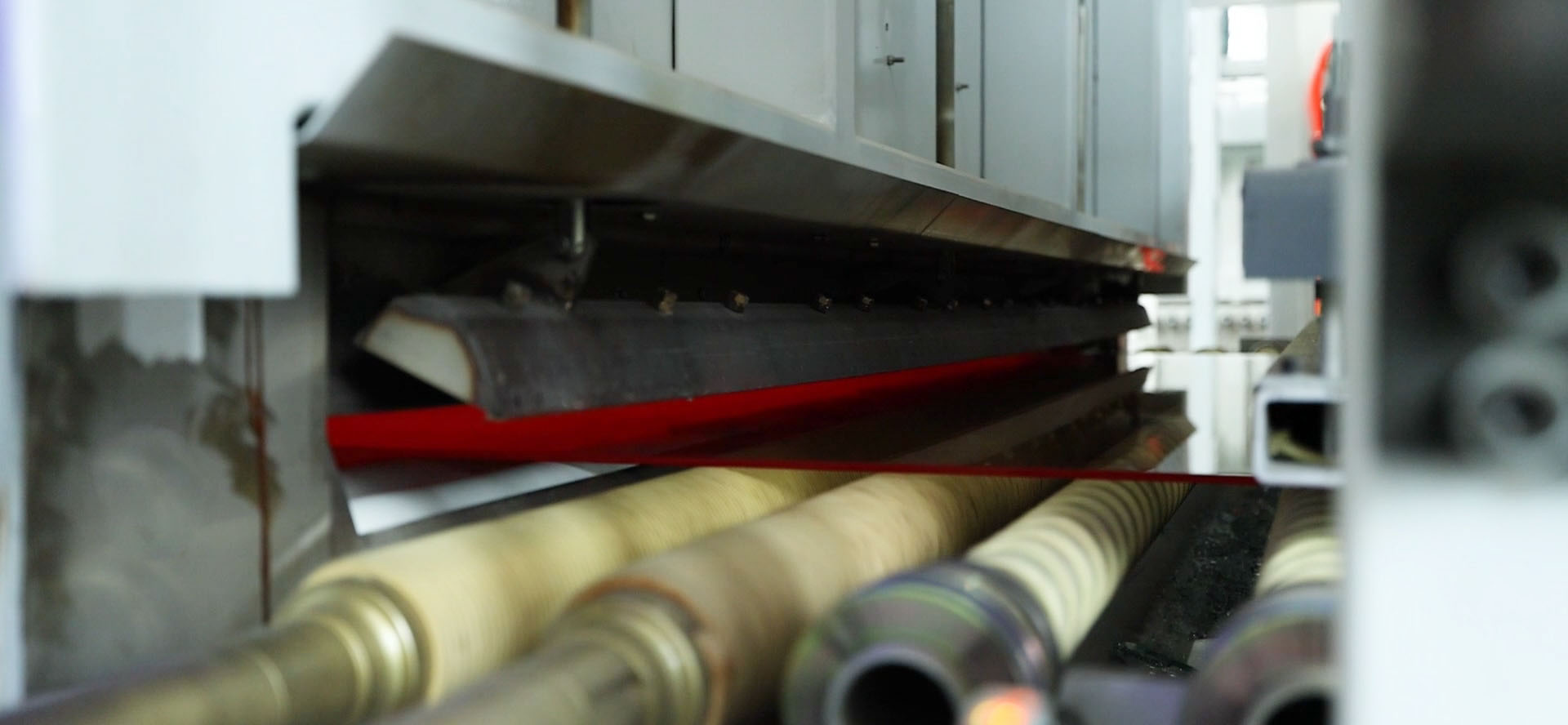

In order to achieve the desired heating effect, the heating furnace must have excellent insulation performance and precise temperature control capability. An efficient insulation layer can help reduce heat loss, maintain the stability of the furnace environment, and ensure the consistency of the heating process. At the same time, advanced temperature control systems can monitor and adjust temperature in real-time, ensuring minimal temperature differences in each area, which is crucial for avoiding cracks or other defects in glass caused by local overheating or undercooling.

2. The importance of uniform heating

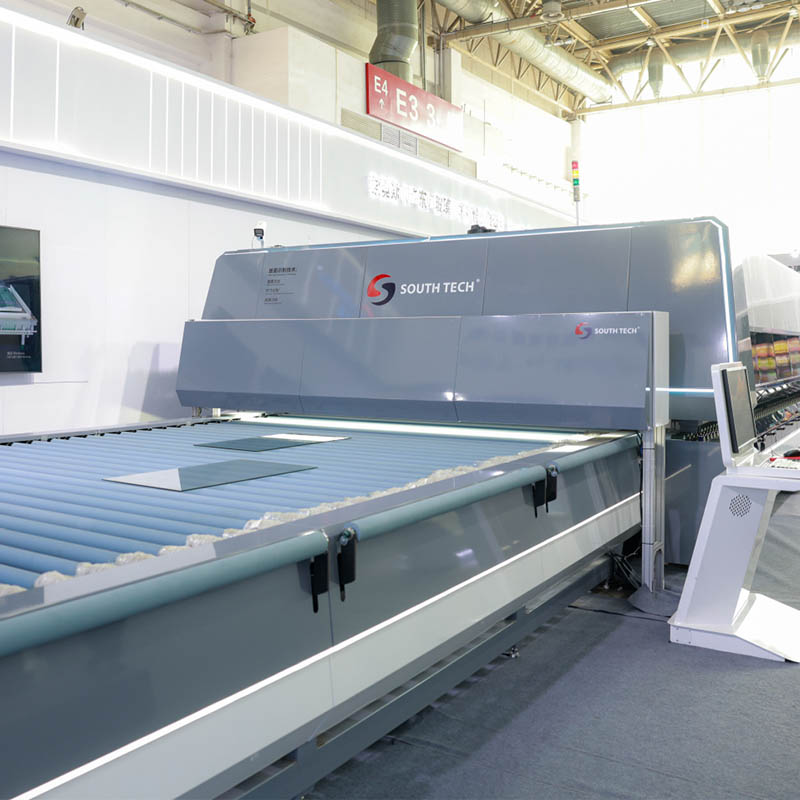

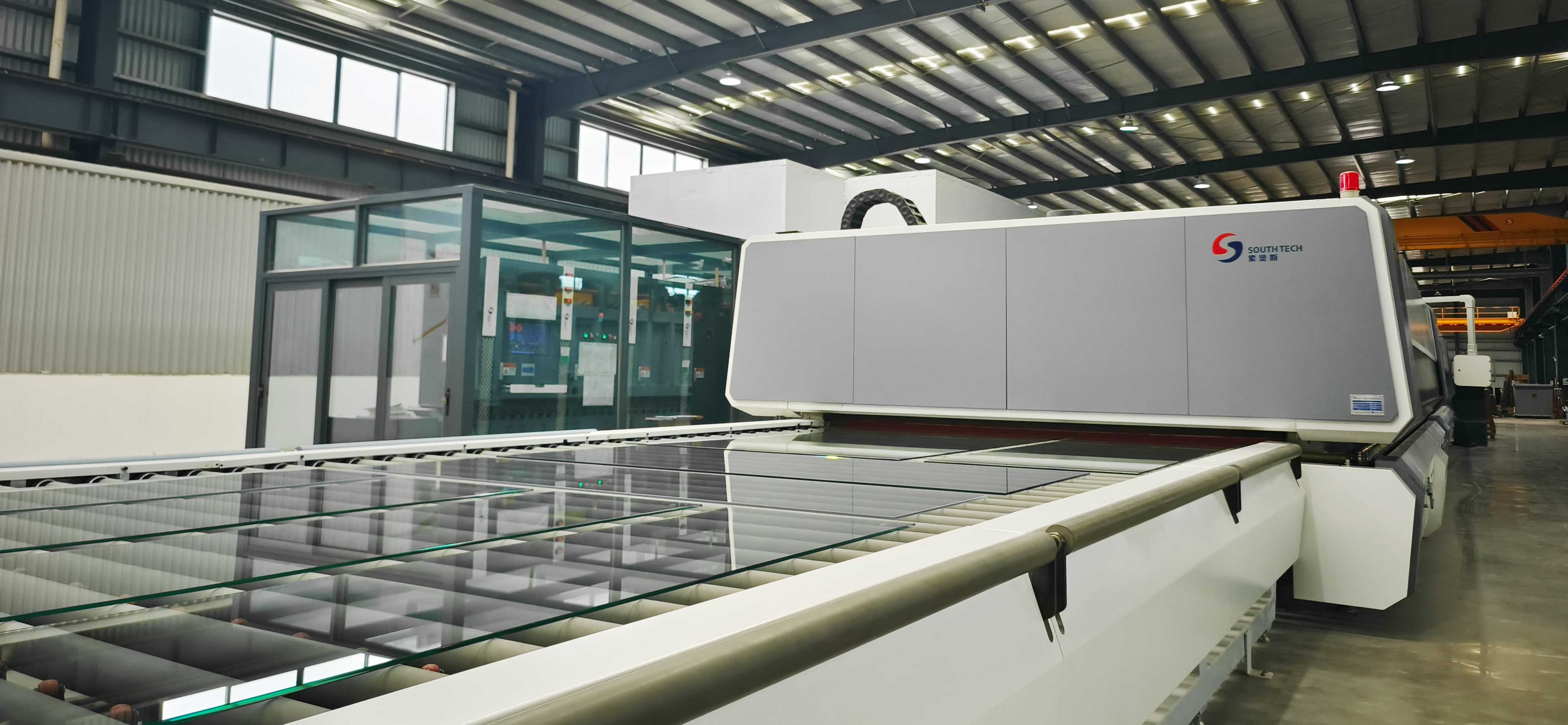

Uniform heating is one of the crucial factors in the process of glass tempering. Any temperature imbalance can lead to uneven stress distribution inside the glass, which not only affects the mechanical properties of the glass, but may also cause optical distortion in the finished product. Therefore, the Southtech glass tempering furnace adopts self-developed fan convection technology to enhance air circulation, ensuring that all parts of the glass can receive uniform heat supply. This method not only improves heating efficiency, but also significantly improves the quality of tempered glass products.

3. The relationship between temperature control and product quality

Accurate setting and strict control of heating temperature are crucial for eliminating residual stresses in glass. If the stress in the glass is not completely eliminated, fracture may occur during the initial quenching stage due to the tensile stress formed at the center. Therefore, a reasonable temperature curve design and precise temperature control strategy are indispensable for producing high-quality tempered glass. The operator should choose appropriate heating parameters based on the specific type and thickness of the glass to achieve the best tempering effect.

The heating furnace body of the glass tempering furnace plays a crucial role in the production of high-quality tempered glass. It not only determines the heating speed and uniformity but also directly impacts the safety and aesthetics of the finished product. As a leading supplier of glass tempering furnaces and a renowned manufacturer, Southtech is dedicated to advancing heating technology and temperature control systems. Through continuous innovation and the development of new technologies, Southtech assists tempered glass producers in meeting stringent safety standards while achieving high aesthetic qualities, thus ensuring the production of superior tempered glass products.