The effect of the passing section of the glass tempering furnace on glass tempering

2024-12-29

The effect of the passing section of the glass tempering furnace on glass tempering

The glass tempering furnace is a key equipment for converting ordinary flat glass into high-strength and high safety tempered glass. Among them, the "through section" (usually referring to the quenching or cooling section) plays a crucial role in the tempering process. This article will explore the role of glass tempering furnaces in improving glass performance through stages.

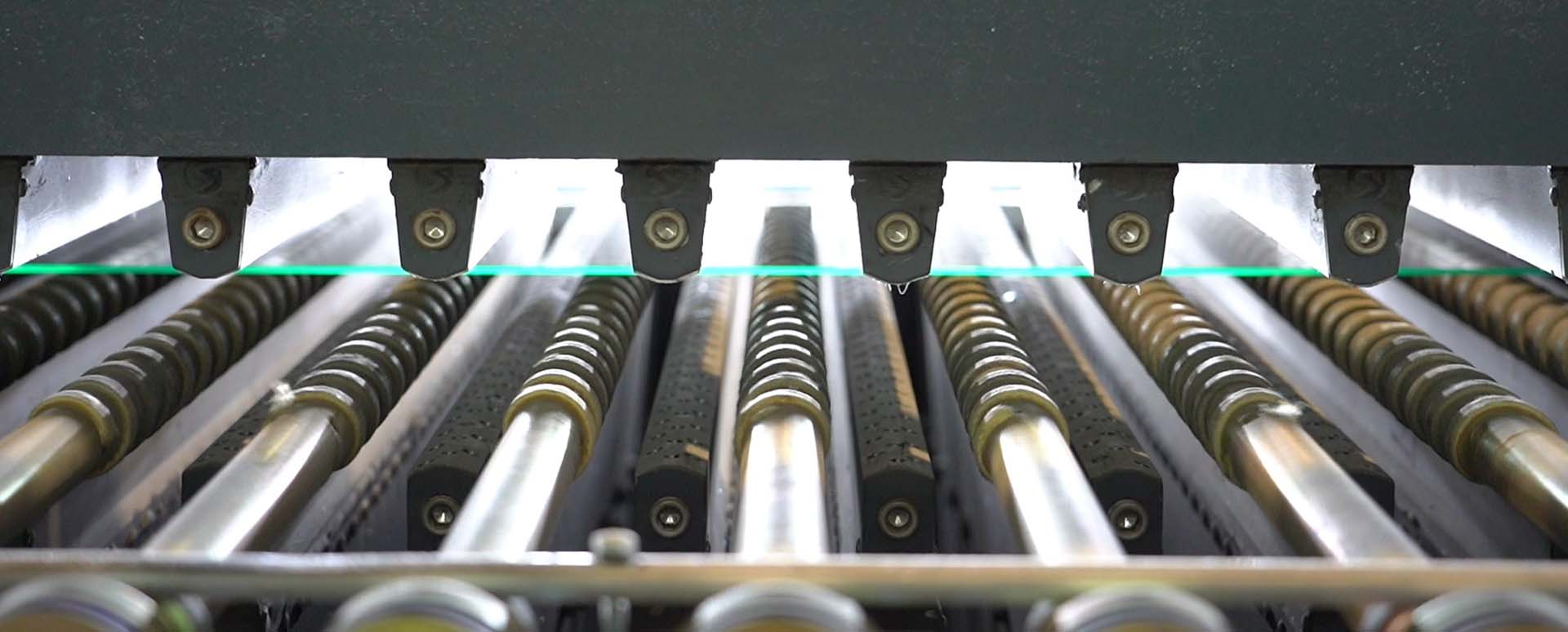

The passing section is a key link in the glass tempering furnace, mainly consisting of three parts: cooling air grille, conveyor roller, and air collection box. The cooling air grille rapidly reduces the temperature of the glass through high-speed cold air spraying, the conveyor roller is responsible for smoothly moving the glass during the cooling process, and the air collection box is responsible for distributing and adjusting the air path to ensure uniform and efficient cooling.

The working principle of the clearance section:

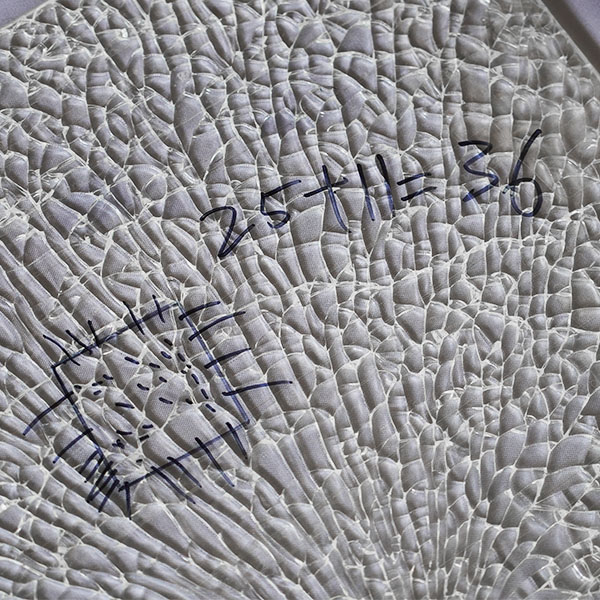

After the glass is heated to a certain temperature through the convection heating section, it enters the passage section where the high-speed cold air from the cooling air grille rapidly and uniformly cools its surface. At the same time, the glass swings back and forth on the roller conveyor, forming a stress distribution of outer layer compression and inner layer tension, in order to improve cooling efficiency and reduce the occurrence of defects such as wind spots, giving the glass higher quality and strength; The design and operation of the section can directly affect the final quality of tempered glass.

Through the role of paragraphs:

In the process of tempering, the role of the section is crucial, as it achieves rapid and uniform cooling of the glass through high-speed cold air. This is particularly important for forming the compressive stress layer of tempered glass, which can maintain the original shape and dimensional accuracy of the glass to the greatest extent possible; The compressive stress layer formed during the cooling process can significantly improve the impact resistance and heat resistance of glass; In addition, the design of the section also helps to reduce the defects of wind spots and uneven stress that may occur during the cooling process of the glass.

The impact of paragraphs on product quality:

As one of the core processes in the production of tempered glass, the performance of segments directly determines the quality level of the final product. The ideal passage can maintain stable cooling conditions between different batches, ensuring that each piece of tempered glass has uniform stress distribution and mechanical properties. Efficient passage not only helps improve the quality of individual products, but also accelerates the overall operation speed of the production line, increases daily output, reduces energy consumption, and meets the production requirements of high efficiency and energy conservation.

glass tempering,glass tempering furnace,glass tempering machine,tempering furnace price,small glass tempering machine