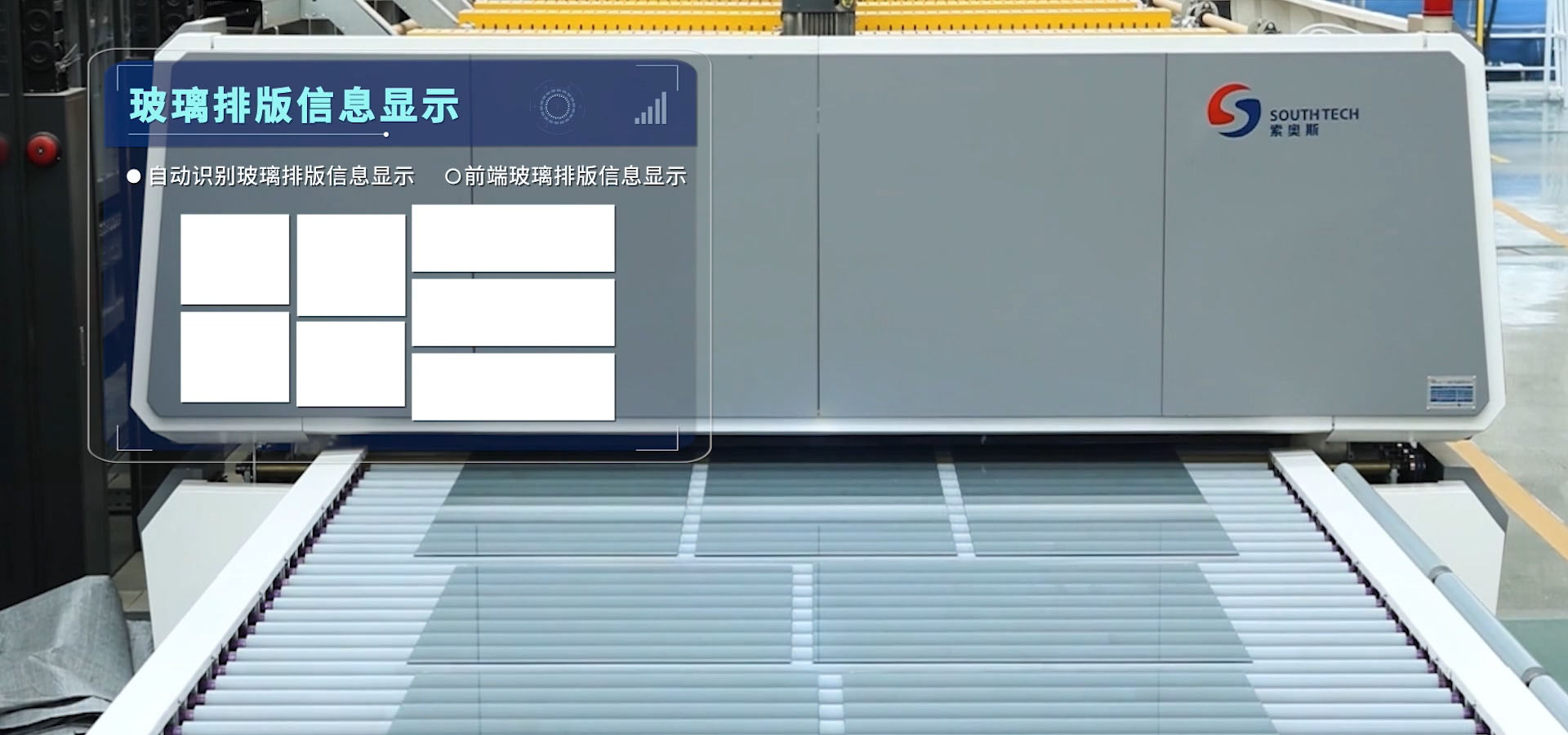

Automatic recognition of glass layout technology for glass tempering furnace

2025-02-15

Automatic recognition of glass layout technology for glass tempering furnace

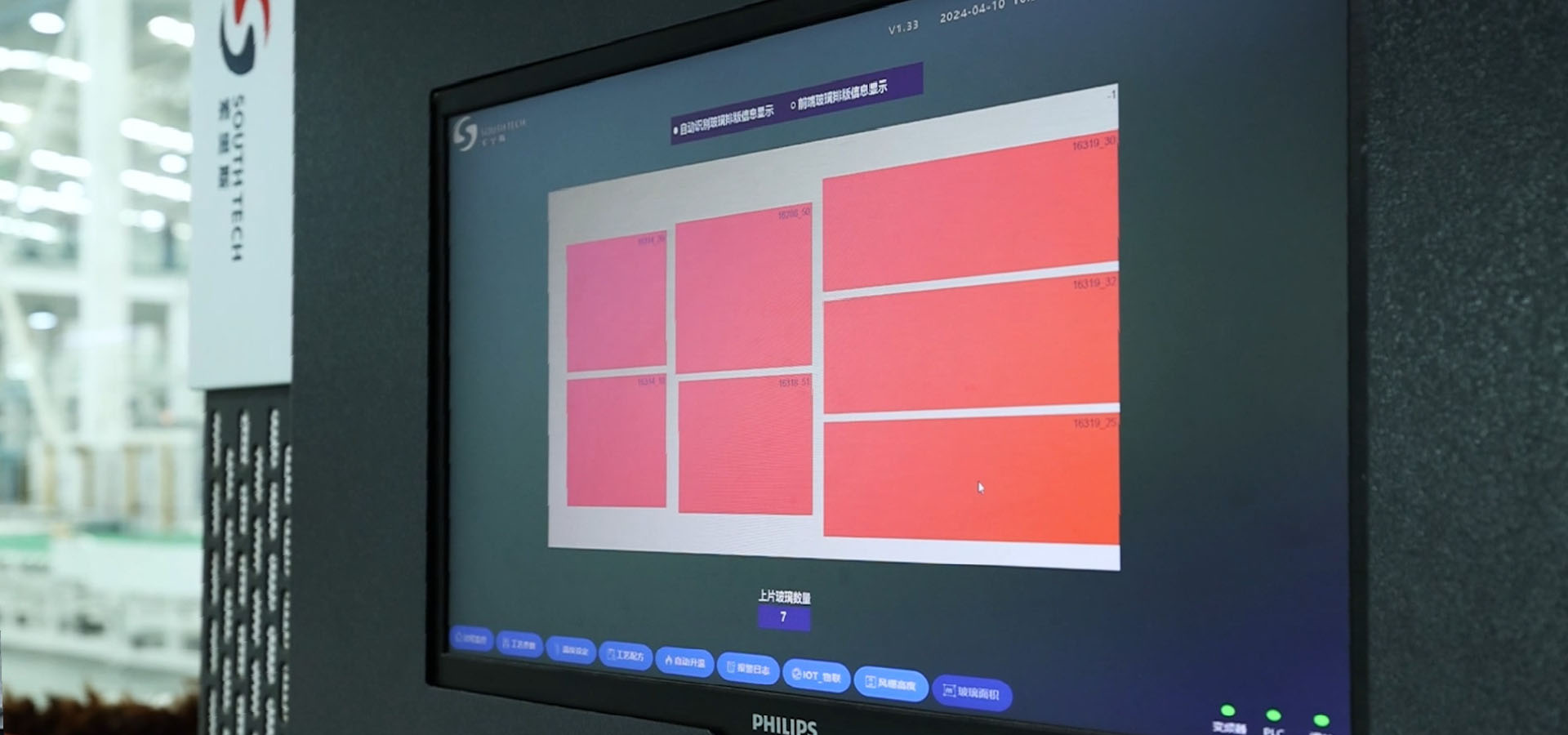

The recognition of glass layout information technology in glass tempering furnaces can significantly improve production efficiency. By automatically identifying the layout information of glass, including but not limited to its size, shape, and specific placement on the conveyor belt, the glass tempering furnace can quickly adjust its parameter settings to adapt to each piece of glass to be processed. This means that there is no need for operators to manually input detailed data for each piece of glass or perform complex preliminary settings, greatly reducing the time interval from preparation to actual processing and improving the overall speed and production capacity of the production line.

Secondly, it helps to ensure the stability of product quality. When the glass tempering furnace has the ability to recognize layout information, it can accurately control factors such as heating area, temperature distribution, and air pressure during the cooling process based on the obtained information, ensuring that each piece of glass can obtain optimal processing conditions. This precise regulation not only reduces the amount of waste generated due to improper handling, but also makes the final glass product more stable.

Furthermore, this technology also plays an undeniable role in reducing operating costs. Due to the improved level of automation, the need for manual intervention has been reduced, allowing enterprises to save on human resource expenses; Meanwhile, the decrease in error rate indirectly reduces the economic losses caused by material waste. In addition, faster turnover time and higher output rate also mean that greater economic benefits can be obtained per unit time.

Finally, with the increasing diversification of market demand, especially the trend of customized orders, equipping with the function of recognizing glass layout information not only promotes technological progress in production processes, but also enables more flexible response to different types of customer needs, providing a solid foundation for achieving higher quality, lower consumption, and stronger adaptability in glass deep processing.