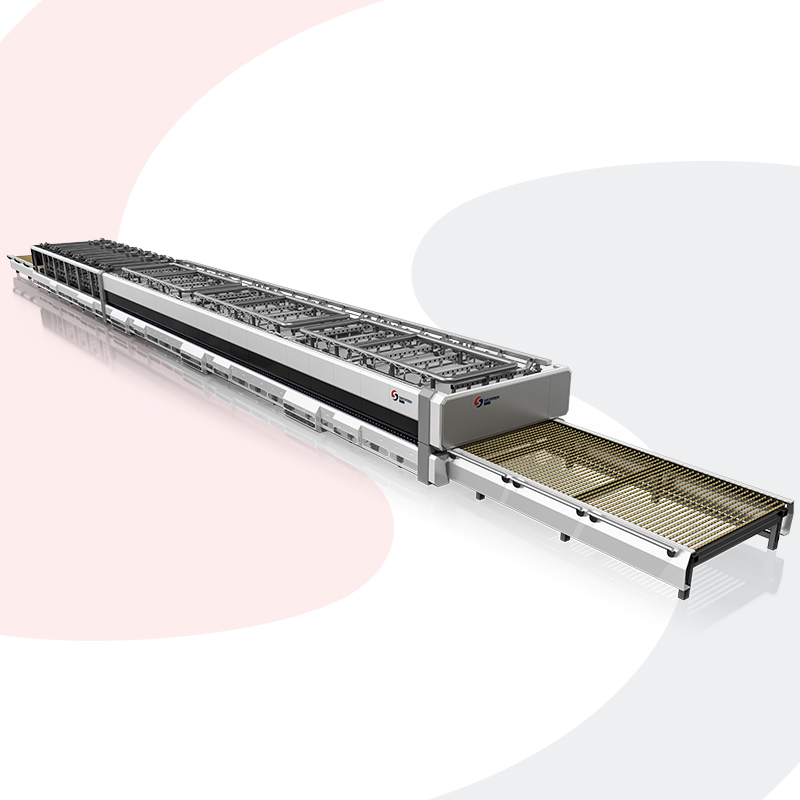

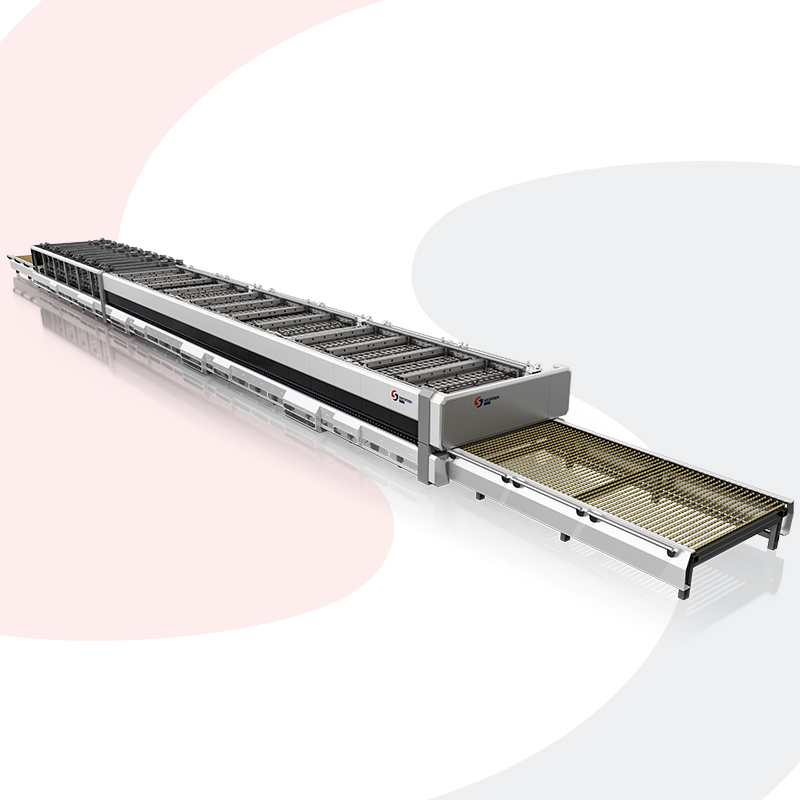

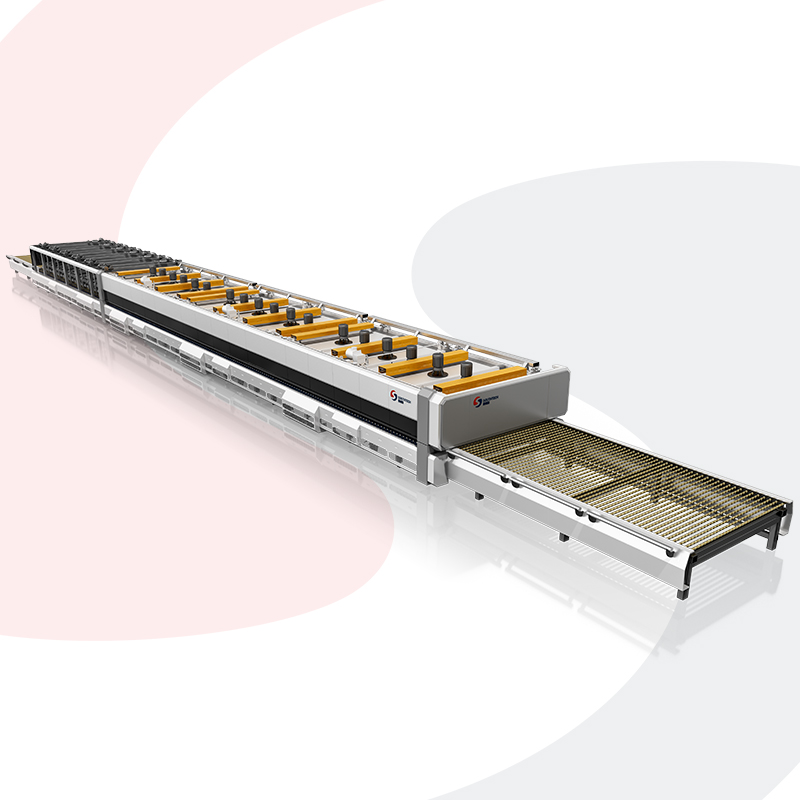

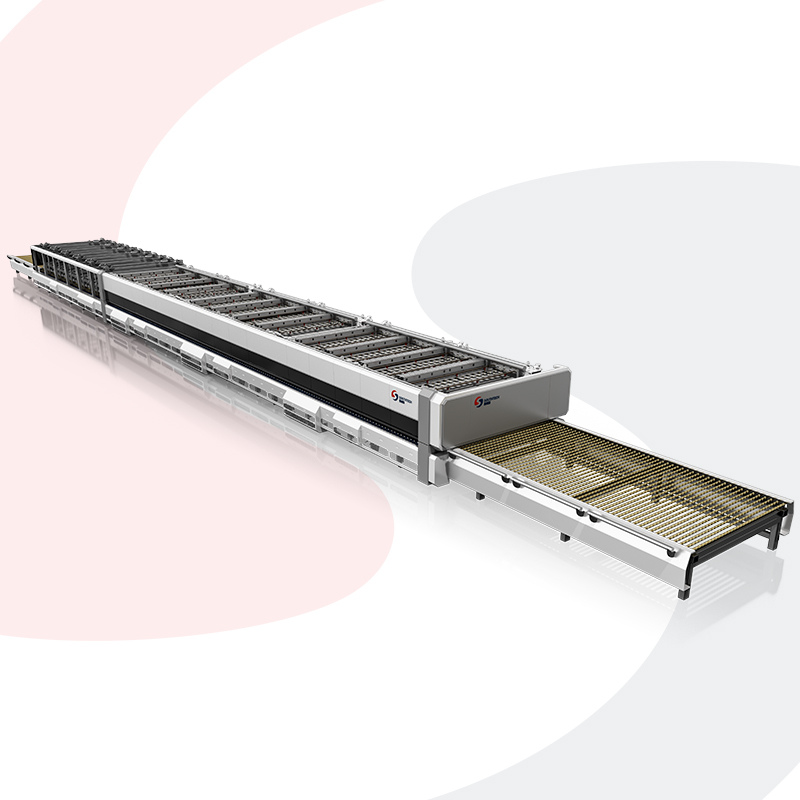

CONTINUOUS MIRROR GLASS TEMPERING MACHINE

Category: Coated glass, Clear Float Glass, Tinted Glass.

- 30000mm x 900mm

- 42000mm x 1200mm

- 350mm x 350mm

- 3.0-6mm

Details

CONTINUOUS MIRROR GLASS TEMPERING MACHINE

SOUTHTECH continuous tempered glass flat tempered machine adopts a multi gradient heating chamber design, significantly shortening the heating cycle while ensuring that the tempered glass has ultra-high optical properties. The unique temperature distribution technology presents a stepped temperature distribution, gradually increasing from low to high temperature, effectively avoiding adverse reactions caused by large temperature differences when glass enters the furnace, ensuring the perfect quality of each piece of glass.

In addition, the introduction of a fast quenching and cooling section opening and closing system enables the glass tempered machine to respond quickly and solve problems in the face of sudden situations inside the quenching and cooling section, further ensuring the continuity and stability of production. The carefully designed unequal spacing arrangement scheme based on the actual deformation of glass during heating ensures that the product is uniformly heated while also ensuring the bending degree of tempered steel.

SOUTHTECH continuous tempered glass flat tempered machine can not only efficiently produce ordinary tempered glass, but also produce high-quality tempered glass. The tempered glass produced not only has clear imaging, but also excellent impact resistance, suitable for multiple industries such as construction and furniture manufacturing, meeting customers' demand for high-quality tempered glass.