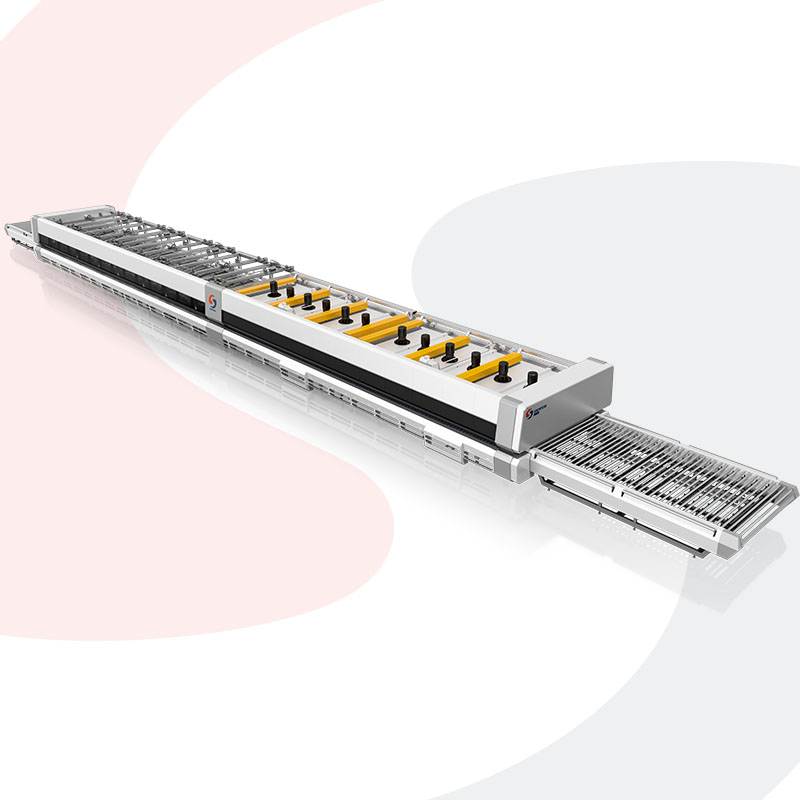

DOUBLE CHAMBER PASSING FLAT GLASS TEMPERING FURNACE

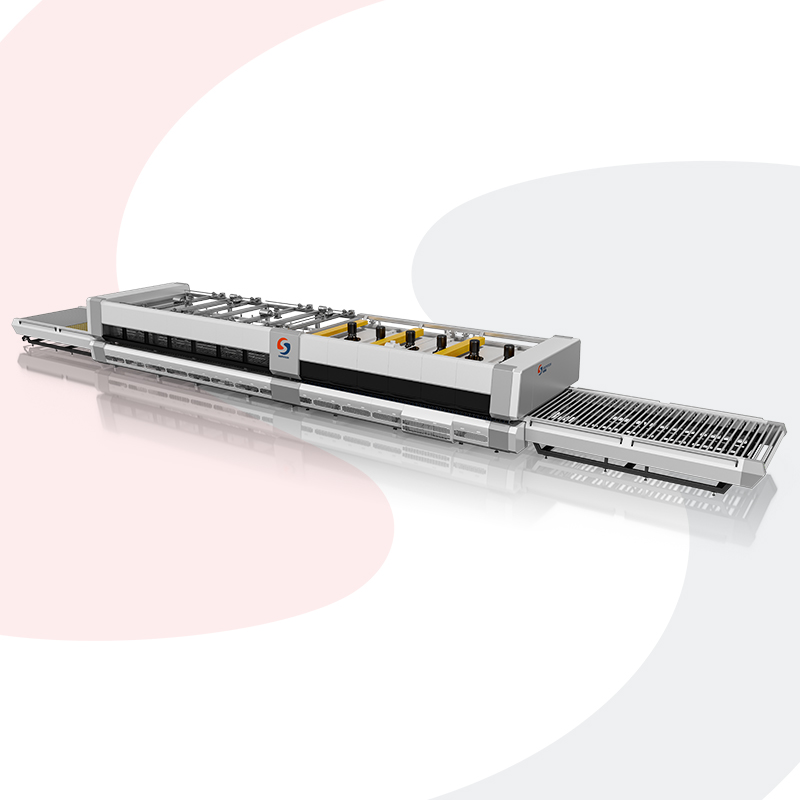

Processing glass Category: Coated glass, Clear Float Glass, Tinted Glass.

- 4000mm×1000mm

- 12000mm×3600mm

- 300mm ×100mm

- 2.85~19mm

Details

DOUBLE CHAMBER PASSING FLAT GLASS TEMPERING FURNACE

SOUTHTECH double chamber glass flat tempered machine has the dual advantages of high efficiency and stability. The glass tempering machine has achieved a significant improvement in production efficiency through optimized design, ensuring fast delivery of large quantities of orders. The design of the dual chamber structure enables seamless connection between heating and cooling processes, minimizing processing cycles and increasing production capacity.

At the same time, the stability of the glass tempering machine has been fully guaranteed, which can maintain efficient operation for a long time without affecting product quality.

SOUTHTECH double chamber glass flat tempered machine, with its excellent performance and reliable performance, provides customers with a one-stop efficient solution, helping enterprises stand out in the fiercely competitive market environment.

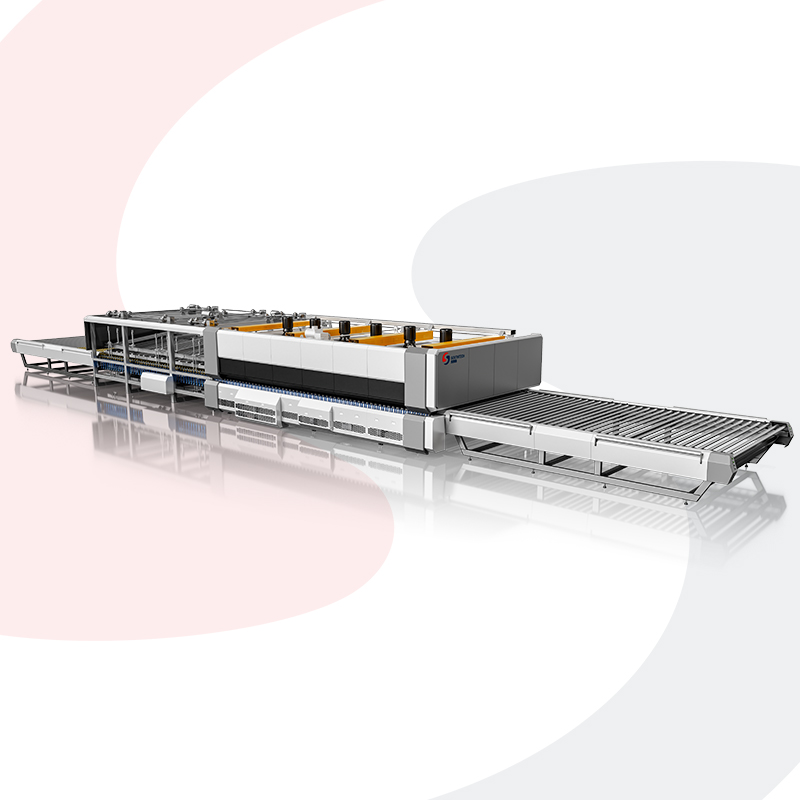

Peculiarity:

1. Adopting a DOUBLE heating chamber design, it can effectively shorten the production cycle, maximize production capacity, and improve fan utilization, achieving the goal of high efficiency and energy conservation.

2. First heating zone is a low-temperature area, and the second heating zone is a high-temperature area; Enable glass to follow a scientific heating temperature curve, reduce adverse reactions of glass after entering the furnace, and improve the surface quality of glass.

3. The cooling section has a double cooling zone, which is designed for high-speed production of thick glass. By adding a cooling second zone, the unloading temperature of the thick plate glass is ensured to reach a range that is easy to handle.