Product recommendation

Preparation before formal production of glass tempering furnace

[ 1 ] After the glass tempering furnace is heated and hold the temperature for half an hour, load the parameter files as needed.

[ 2 ] After loading the files, press the “Change” button in “Technological parameter” page, and then click “OK” . The heating time, quenching time, cooling time, the temperature of each heating zone will be adjusted according to the new file automatically. This process takes 10 minutes.

[ 3 ] After starting the air blowers, the lass tempering furnace can produce normally (Please notice that when your start the blowers, the opening and damper of blower should be closed).

[ 4 ] Run the furnace for 2-3 times in simulation. Please confirm whether the settings of the thermal equilibrium pressure and the quenching air pressure is OK or not. Make sure the air blowers work normally and there’s no abnormal sound or noise in the running equipment.

Glass Tempering Furnace,Glass Tempering Line,Glass Tempering Machine,Glass Tempering Oven,Southtech Glass Tempering Furnace

Please visit product page for more information

-

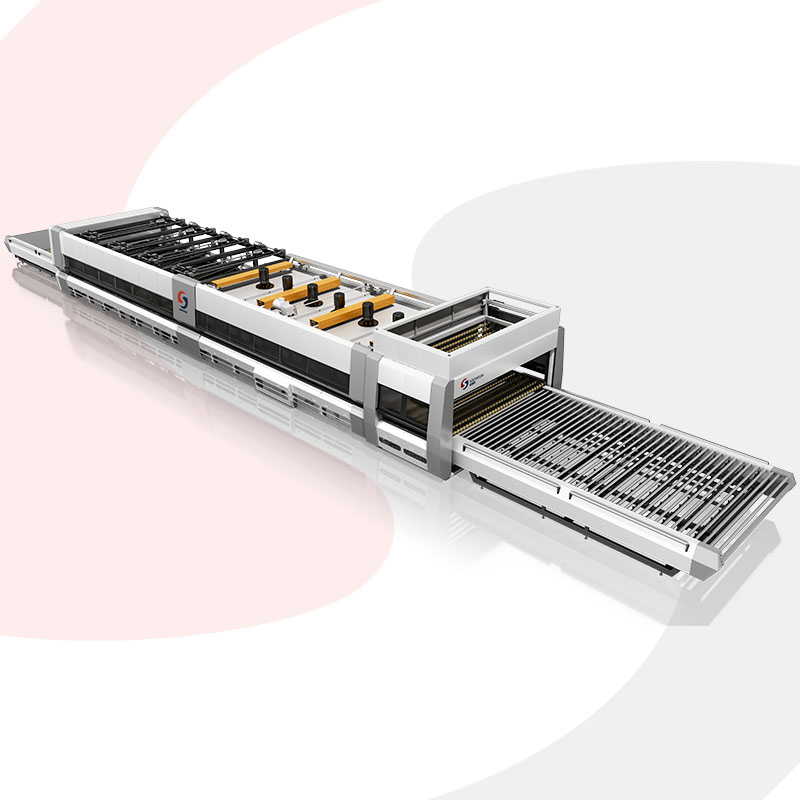

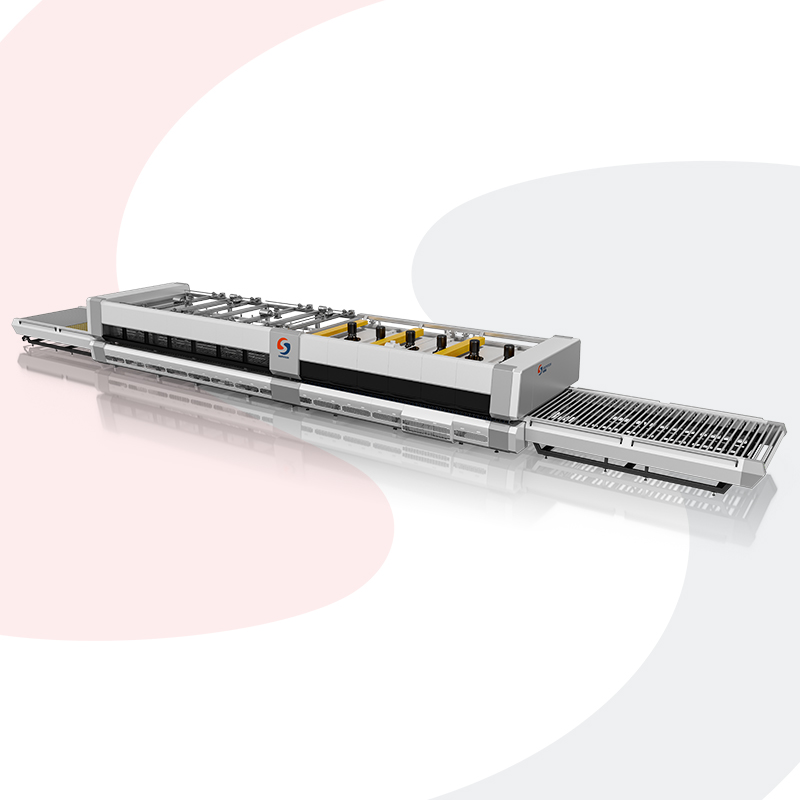

BENT GLASS TEMPERING MACHINE WITH HI-TECH CONVECTION SYSTEM

Category: Coated glass, Clear Float Glass, Tinted Glass, LOW-E Glass(Single, double and triple sliver).

More

-

- Southtech Showcases at India’s glasspro Expo: Focusing on Customer Needs and Exploring Collaborations

- Practical Guide: How to scientifically distinguish tempered glass

- Southtech pioneers the "Horizontal Roller Hearth Tempering Furnace" group standard, setting a definitive industry benchmark.

- Glass Tempering Furnace: Science Popularization of Core Equipment for Safety Glass