Product recommendation

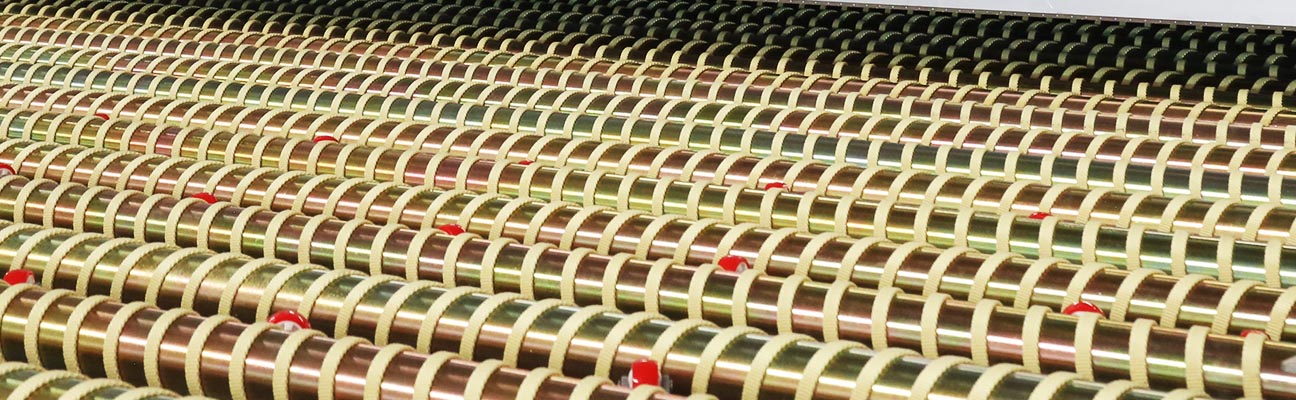

Attentions of the Aramid rope replacement

During production, the Aramid rope winding on the quartz ceramic rolls will be easily damaged by the glass fragments. Therefore, the glass fragments should be cleaned away before production. If the Aramid rope has broken, please repair or replace it immediately.

1. After dismantling the damaged Aramid rope, make sure the Gelatinous substance and other adhesive have been completely removed from the surface of the quartz ceramic rolls so that the surface can keep clean.

2. When winding the Aramid rope, strain it and make it flat and straight. The rope should be uniformly wound in the opposite direction to the ropes on the adjoining quartz ceramic rolls.

3. When winding the Aramid rope, the inter side of Aramid rope should be glued to stick on the rollers. Make sure that no glue is on the outer side of the Aramid rope. This can prevent that the cullet stick on the rollers after the glass bursts.

4. The Aramid rope should be fixed by it’s rope hole firmly and reliably, the fixed screwhead can’t be installed peep through the quartz ceramic roll.

The glue for gluing the Aramid rope is mixed by epoxy resin and hardener of 1:1.

5. When replacing the Aramid rope, please pay attention on the following points if winding the Aramid rope without dismantling the quartz ceramic roll:

[ 1 ] Rise the upper chiller to the top, both ends should be plugged by the insurance sticks. Then underlay the chiller with wood or the other upholder before the operation.

[ 2 ] The quartz ceramic roll should not be load-bearing, otherwise it will be bent and effect the quality of the glass.

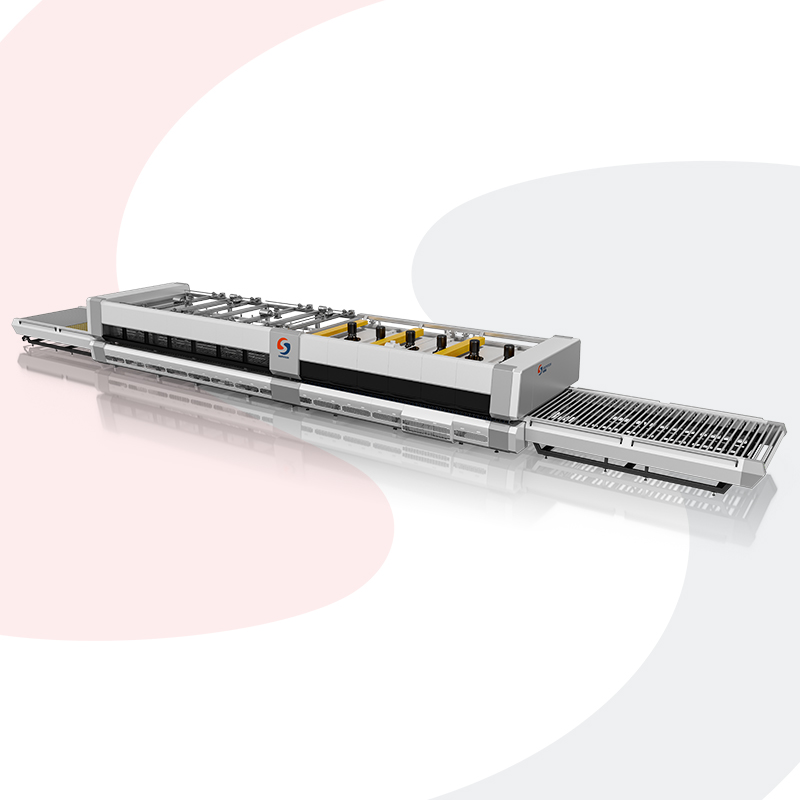

glass tempering furnace,glass tempering oven,glass tempering machine,southtech glass tempering furnace,Tempering furnace accessories

Please visit product page for more information

-

- Southtech Showcases at India’s glasspro Expo: Focusing on Customer Needs and Exploring Collaborations

- Practical Guide: How to scientifically distinguish tempered glass

- Southtech pioneers the "Horizontal Roller Hearth Tempering Furnace" group standard, setting a definitive industry benchmark.

- Glass Tempering Furnace: Science Popularization of Core Equipment for Safety Glass