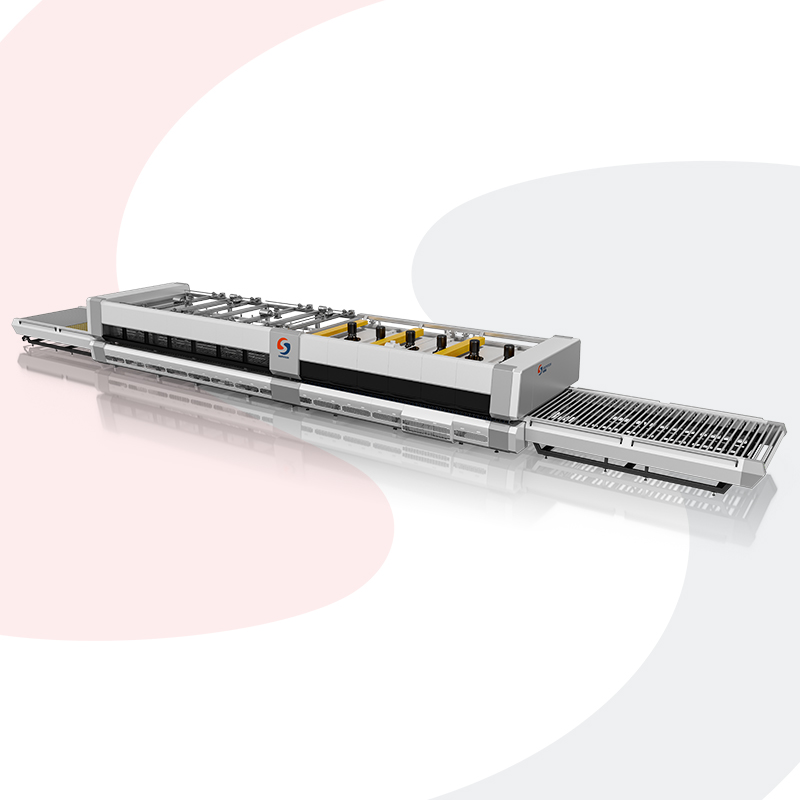

Product recommendation

How to choose and purchase a suitable glass tempering furnace

Choosing and purchasing a suitable glass tempering furnace requires comprehensive consideration from multiple dimensions by the enterprise. By carefully analyzing their own needs and market trends, combined with the product information and service content provided by glass tempering furnace suppliers, enterprises can select the most suitable glass tempering furnace for themselves, thus laying a solid foundation for the company's long-term development. Here are a few important factors to consider.

1. Clarify product positioning:

Before deciding to purchase a glasstempering furnace, the enterprise must first clarify its market positioning, that is, whether the product is mainly aimed at B-end customers or C-end customers. B-end customers usually refer to engineering projects, which are characterized by relatively uniform specifications and large quantities; And C-end customers refer more to the retail market, with diverse and dispersed order characteristics. Different types of customers have different requirements for product quality and specifications. Therefore, when selecting a glass tempering furnace, it is necessary to choose the corresponding equipment configuration according to the specific needs of the target market.

2. Consider production capacity demand:

Capacity is one of the important considerations when choosing a glass tempering furnace. Enterprises should choose the matching tempering furnace model based on their annual production estimation. For example, if it is expected to produce approximately 1.5 million square meters of 5mm Low-E glass annually, then it may be considered to choose a glass tempering furnace with an hourly capacity of 15 -18 furnaces to ensure that production capacity matches market demand. In addition, it is necessary to consider the potential for future business growth to avoid premature obsolescence of equipment.

3. Pay attention to the technical characteristics of the equipment:

(1) Stability of temperature control:

The stability of temperature control is crucial for ensuring the quality of tempered glass. Stable temperature control can ensure the uniformity of glass during heating, which in turn affects the quality of the final product. Therefore, when purchasing, it is important to focus on whether the temperature control system of the equipment can maintain stability throughout the entire production cycle.

(2) Heating speed and cooling effect:

Efficient heating speed and uniform cooling effect are key to ensuring the strength and surface quality of tempered glass. First class tempering furnaces typically use advanced heating and cooling technologies to achieve these goals.

4. Energy conservation and consumption reduction:

With the increasing awareness of environmental protection, energy conservation and consumption reduction have become an indispensable aspect when choosing a tempering furnace. Efficient energy utilization not only reduces production costs, but also promotes sustainable development of enterprises. When choosing equipment, priority should be given to glass tempering furnaces that use high-efficiency and energy-saving technologies.

5. Level of operational intelligence:

The degree of operational intelligence can directly affect the level of production efficiency. A control system equipped with intelligent automation can greatly reduce the training costs for operators and lower the incidence of human errors. Soos glass tempering furnaces are often equipped with intelligent automation control systems, making operation more efficient and convenient.

6. Maintenance and after-sales service of equipment:

High quality maintenance services and a comprehensive after-sales service system are the foundation for ensuring the long-term stable operation of equipment. Before purchasing, it is recommended to have a thorough understanding of the supplier's after-sales service, including whether there is a professional technical support team, repair response time, and parts supply situation. A good after-sales service can provide timely and effective solutions when equipment problems occur, ensuring the continuity of production.

Glass Tempering Furnace, Glass Tempering Oven, Glass Tempering Furnace Price, Southtech Glass Tempering Furnace,Glass Tempering Furnace Manufacturers

Please visit product page for more information

-

- Southtech Showcases at India’s glasspro Expo: Focusing on Customer Needs and Exploring Collaborations

- Practical Guide: How to scientifically distinguish tempered glass

- Southtech pioneers the "Horizontal Roller Hearth Tempering Furnace" group standard, setting a definitive industry benchmark.

- Glass Tempering Furnace: Science Popularization of Core Equipment for Safety Glass