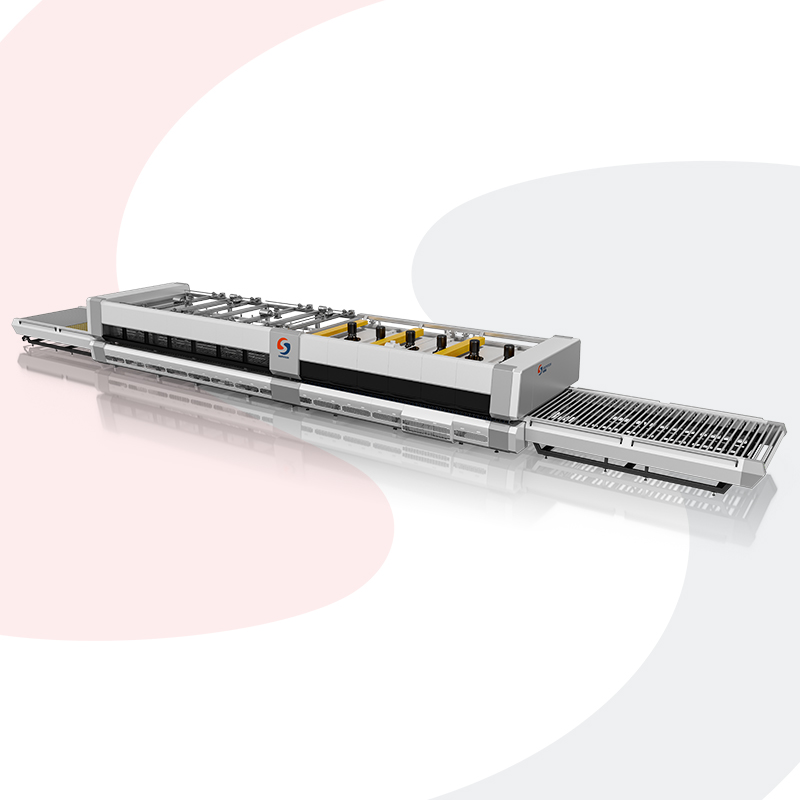

Continuous Flat Glass Tempering Production Line By DIYA Glass

Southtech Continuous Flat Glass Tempering Furnace By Diya Glass

In modern homes, high-quality glass products play a vital role. As an important part of home glass, the quality and performance of shower room glass directly affect the use and safety of users. The continuous flat glass tempering furnace customized by Southtech for Diya Glass is specially designed for the production of home glass such as shower room glass. With its advanced technology, excellent performance and efficient production capacity, it has become an ideal choice for home glass manufacturers.

MES Connection And Intelligent Process Matching

Automatically obtain and match process parameters:

Through MES system access, automatically obtain glass information, intelligently match the optimal process parameters in the formula library, and automatically switch equipment parameters. Improve switching efficiency, reduce manual intervention, save time and cost, make the production process more efficient and automated, and improve the production efficiency and economic benefits of the enterprise.

Machine learning improves matching accuracy:

Through the accumulation of production process data and automatic learning, continuously optimize parameter matching accuracy, and gradually achieve more accurate process adjustments. Ensure the consistency of product quality in multiple batches, reduce the defective rate, and improve the market competitiveness of products and the economic benefits of enterprises.

Human-machine collaboration and ease of operation:

Automated process switching simplifies the operation process, reduces the burden of manual recording of production data, and improves ease of operation. Reducing labor costs and improving the operating efficiency of tempering furnaces enable enterprises to produce more efficiently and improve their market competitiveness.

Wide Applicability To Meet Diverse Needs

Processing capabilities of various glass categories:

The production line can process a variety of glass categories, including tempered coated glass, transparent float glass, body tinted float glass, and LOW-E glass (single silver, double silver, and triple silver). The glass tempering furnace can easily cope with and meet different tempering production needs.

Processing of different sizes and specifications:

The glass tempering furnace equipment parameters are flexible, with a maximum loading area of 3000mmx2000mm, a minimum processing size of 400x400mm, and a processable thickness of 4~6mm. This wide range of size processing can meet the requirements of different home spaces for shower room glass sizes. Whether it is a simple shower room for a small apartment or a luxurious shower room for a large space, it can provide suitable glass products.

The Southtech continuous flat glass tempering furnace provides a one-stop solution for Diya Glass with its advanced technology, efficient performance and wide applicability. Choosing the Southtech means choosing high quality, high efficiency and high competitiveness, helping enterprises stand out in the fierce market competition.