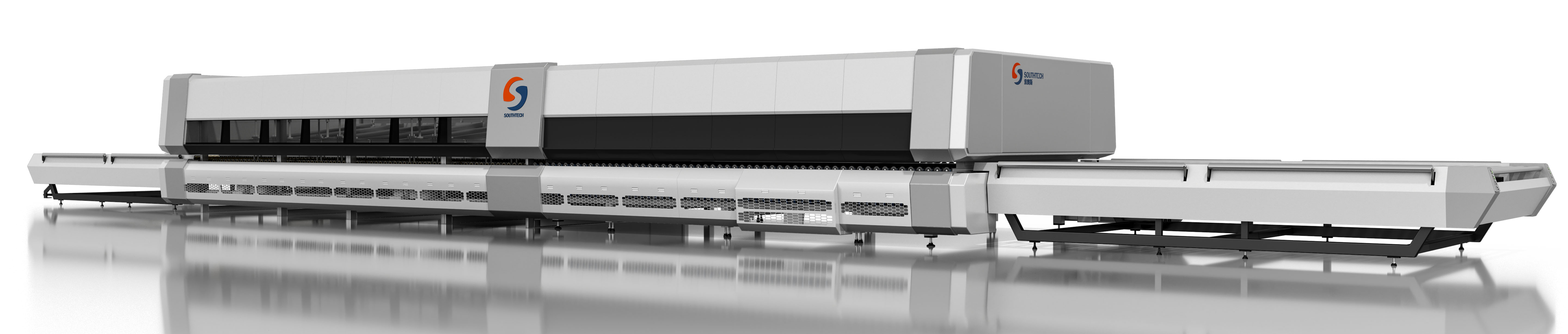

The role of cooling air grille in glass tempering furnace

2024-12-30

The role of cooling air grille in glass tempering furnace

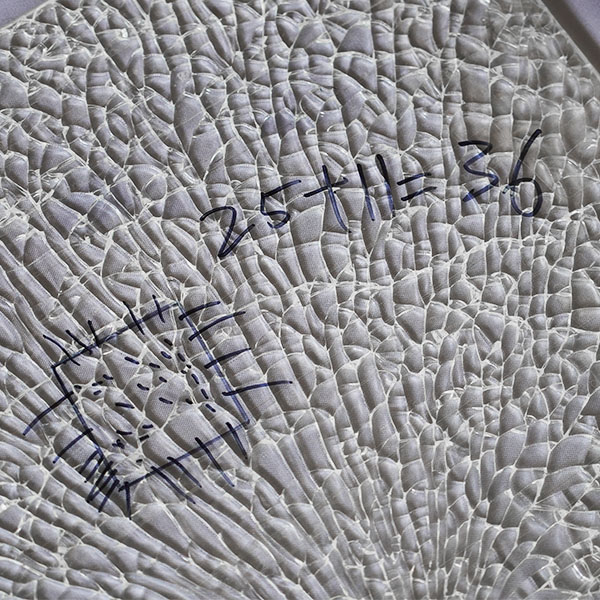

The cooling air grille of a glass tempering furnace is one of the key components in the production process of tempered glass. Its main function is to form a compressive stress layer on the surface of the glass and a tensile stress layer inside through rapid cooling after the glass is heated to near the softening point, thereby improving the mechanical strength and safety of the glass. The following are the specific functions and technical characteristics of cooling air grilles:

1. Rapid cooling:

Forming a compressive stress layer: The cooling air grille evenly sprays cold air onto the glass surface through a high-pressure fan, rapidly cooling the glass surface and forming a compressive stress layer. This compressive stress layer can significantly improve the impact strength and bending strength of glass.

Control cooling rate: The cooling air grille can automatically adjust the distance between the grille and the glass according to the thickness and type of glass, ensuring a moderate cooling rate and avoiding glass quality problems caused by too fast or too slow cooling.

2. Uniform cooling:

Upper and lower grille design: The cooling grille is divided into upper and lower parts, which are respectively connected to the air distribution center to ensure that cold air can be sprayed from both the upper and lower surfaces of the glass, achieving uniform cooling.

Multi exhaust vents: The vents on the grille are usually designed in multiple rows, and the distance and arrangement between the vents are optimized to ensure that the cold air can evenly cover the glass surface, reducing the problems of wind spots and uneven cooling.

Wind volume and pressure regulation: By adjusting the frequency of the fan motor through a frequency converter, the air volume and pressure can be precisely controlled to meet the cooling needs of different thicknesses and types of glass.

3. Improve cooling efficiency:

Efficient nozzle design: The air vent design of the grille is based on fluid mechanics principles, optimized through extensive calculations and experiments, to ensure that cold air can be sprayed onto the glass surface at high speed and efficiency.

Height adjustment of air grille: The height of the cooling air grille can be electrically adjusted, and the distance between the air grille and the glass can be automatically adjusted according to the thickness and type of glass, so that the spraying distance is always at the optimal value, improving the cooling effect.

4. Prevent glass deformation:

Glass swing: During the cooling process, the glass will swing back and forth on the conveyor roller to ensure that the cold air can evenly cover the surface of the glass and reduce deformation caused by rapid local cooling.

Roller conveyor design: The conveyor roller under the cooling air grille has been specially treated with aramid protection on the surface to prevent glass from being scratched on the roller conveyor, while ensuring that the glass does not deviate and improving the surface quality and yield of the glass.

5. Intelligent control:

Automated control system: The operation of the cooling air grille is automatically completed by an intelligent control system, and all process parameters can be pre-set and dynamically adjusted during the control process to ensure precise control of the cooling process. At the same time, operators can set and adjust various process parameters through the control system to improve production efficiency and product quality.

6. Maintenance and upkeep:

Regular cleaning: The cooling grille needs to be cleaned regularly to prevent blockage of the air holes and contamination of the grille surface, ensuring cooling effectiveness.

Wind grille inspection: Regularly inspect the air holes, nozzles, and structure of the wind grille to ensure that they are intact and avoid production problems caused by wind grille failures.

The cooling air grille of the glass tempering furnace forms a compressive stress layer on the surface of the glass and a tensile stress layer inside through a rapid and uniform cooling process, thereby significantly improving the mechanical strength and safety of the glass. Its efficient design and intelligent control system ensure the accuracy and reliability of the cooling process, making it an indispensable key component in tempered glass production.

glass tempering furnace,tempering furnace cooling air grille,glass tempering furnace technology,cooling air grille,tempered glass