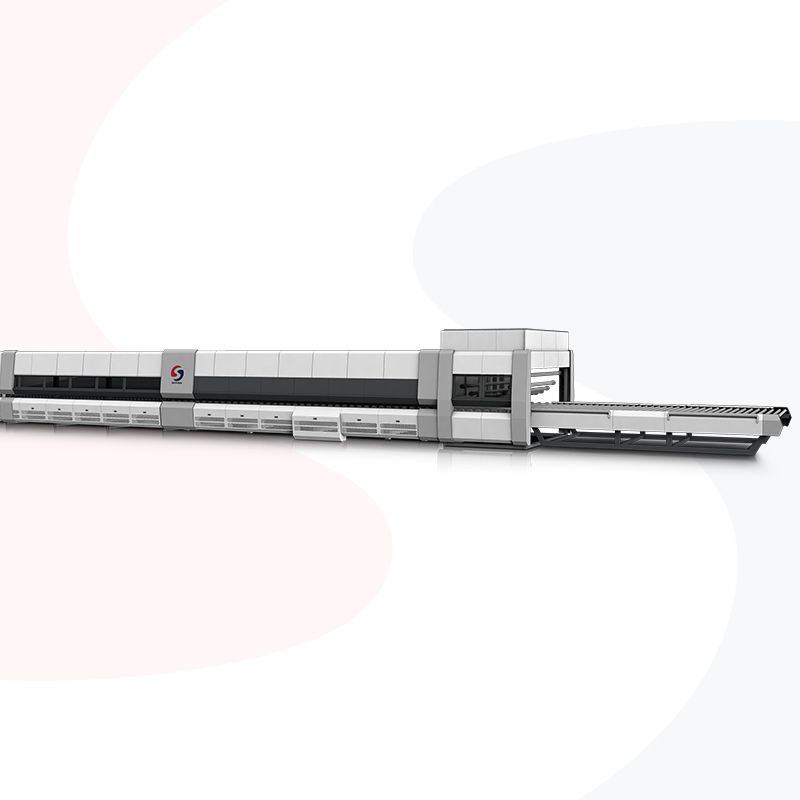

FLAT AND BENT GLASS TEMPERING MACHINE WITH VORTECH CONVECTION SYSTEM

Minimum model of flat section: 4000mm x 1000mm

Maximum model of flat section: 6000mm x 3000mm

Minimum model of bent section: Curved 700mm x 1000mm

Maximum model of bent section: Curved 3000mm x 6000mm

Flat glass processing thickness: 2.85-19mm

Flat glass processing minimum size: 300mm x 100mm

Bent glass processing thickness: 3.2mm~19mm

Bent glass processing minimum size: Curved 400 x 400mm

Category: Coated glass, Clear Float, Glass

Tinted Glass, LOW-E Glass(Single, double and triple sliver).

Details

FLAT AND BENT GLASS TEMPERING MACHINE WITH VORTECH CONVECTION SYSTEM

SOUTHTECH intelligent VORTECH convection glass flat and bending tempering machine, it adopts a VORTECH convection structure, which not only optimizes the temperature uniformity during the heating process, but also improves the cooling efficiency, ensuring that each piece of glass can achieve the best tempering effect, and has the ability to temper offline Low-E glass, ensuring excellent energy-saving performance of the finished product.

By adopting advanced CNC machining technology, the glass tempering machine can accurately control the bending accuracy of glass and achieve precise molding. The simple computer arc adjustment structure further simplifies the operation process, significantly reduces adjustment time, and improves production efficiency and flexibility.

The unique roller structure design effectively reduces the length of straight edges at both ends of the arc, making the finished product lines smoother and the appearance more beautiful. In addition, the glass tempering machine also has the function of using bending section to produce flat tempered glass, which broadens the application scenarios of the glass tempering machine.