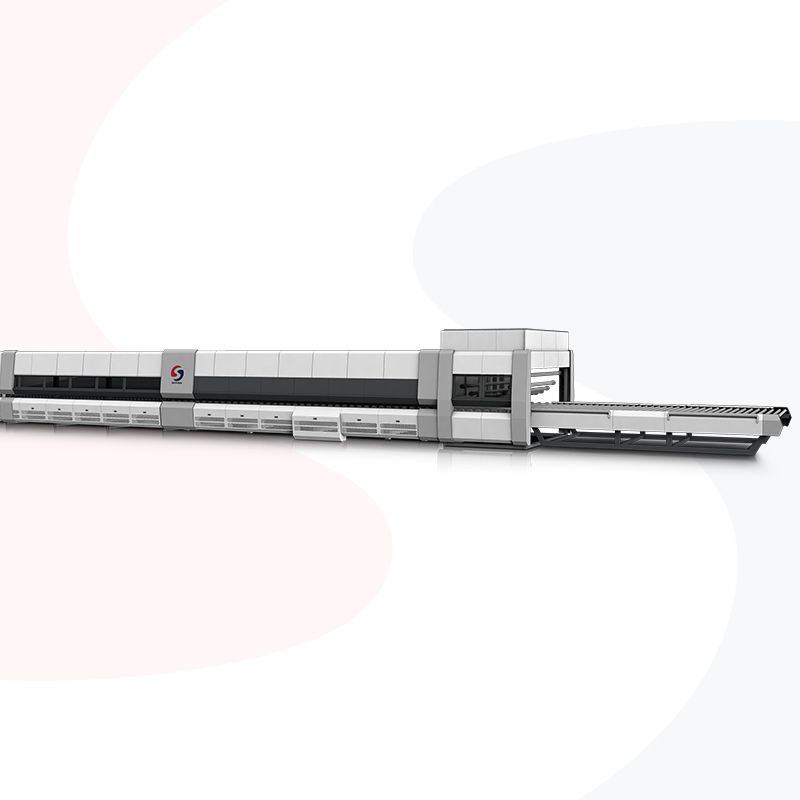

HIGH BOROSILICATE FLAMEPROOF FLAT AND BENT GLASS TEMPERING MACHINE WITH VORTECH CONVECTION SYSTEM

Minimum model of flat section: 5000mm x 2000mm

Maximum model of flat section: 6000mm x 2600mm

Minimum model of bent section: Curved 700mm x 2000mm

Maximum model of bent section: Curved 2600mm x 6000mm

Flat glass processing thickness: 3.3-19mm (float glass) 5-10mm (high boron silicon 4.0mm glass, high stress glass)

Flat glass minimum size: 300mm x 300mm

Bent glass processing thickness: 3.2~19mm

Bent glass minimum size: Curved 400mm x 400mm

Category: Coated glass, Clear Float Glass, Tinted Glass.

Details

HIGH BOROSILICATE FLAMEPROOF FLAT AND BENT GLASS TEMPERING MACHINE WITH VORTECH CONVECTION SYSTEM

SOUTHTECH high borosilicate fireproof glass flat bending tempering machine can temper high borosilicate 4.0 single piece fireproof glass and single piece high stress fireproof glass. The stress value of 6mm single piece high stress fireproof glass is ≥ 160-180MPa, ensuring the high strength and excellent fire resistance of the product. The glass tempering machine adopts a new generation of ultra-high pressure energy-saving fans, which not only improves the efficiency of cooling, but also achieves the goal of energy conservation and emission reduction. It is also equipped with a brand new "Simba" fireproof series heating section structure and rapid cooling section structure, ensuring temperature uniformity and stability during heating and cooling processes, laying a solid foundation for the production of high-quality fireproof glass.

The maximum design width of the equipment can reach 3 meters, meeting the production needs of fire-resistant glass with large layouts. Advanced CNC machining methods can accurately control the bending accuracy of glass and achieve precise molding. The simple computer arc adjustment structure further simplifies the operation process, significantly reduces adjustment time, and improves production efficiency and flexibility. The unique roller structure design effectively reduces the length of straight edges at both ends of the arc, making the finished product lines smoother and the appearance more beautiful.

In addition, the glass tempering machine also has the function of using bending section to produce flat tempered glass, further expanding the application scope of the production line. The Suos high borosilicate fireproof glass flat bending and tempering production line, with its comprehensive technical advantages and excellent performance, has become a reliable choice to ensure the safety of life and property.