Product recommendation

Practical Guide: How to scientifically distinguish tempered glass

1、Verify 3C Certification: intuitive verification of authoritative certification

The "ID card" of tempered glass - the 3C certification mark, is the most direct basis for determining its authenticity. According to national standards, all tempered glass used in buildings must pass CCC mandatory product certification and be permanently marked with certification marks near the corners or cutting surfaces of the glass. This logo is usually made by laser engraving or high-temperature ink firing, and has the following characteristics:

Tactile three-dimensional: The surface of the mark has distinct concave and convex features, and a clear texture can be seen when reflected.

Non-erasable: The mark cannot be easily removed with fingernails or hard objects; if it can be easily wiped off, the product may be counterfeit.

Authoritative verification: Merchants can provide complete authentication documents, and consumers should actively request and verify them.

Reminder: Some small workshops may forge the 3C mark. It is recommended to prioritize purchasing through legitimate brand channels and keep the purchase voucher for rights protection.

2、Observing Stress marks: Optical Detection from a Professional Perspective

During the manufacturing process of tempered glass, after quenching, a compressive stress layer is formed on the surface and a tensile stress layer is formed inside. This stress distribution can cause birefringence when light passes through, resulting in unique Stress marks. This is an important optical characteristic of tempered glass.

Testing method:

Adjust angle: Tilt the glass to a 30-45 degree angle to avoid direct viewing.

Light source: Observe the reflection towards the sky or a uniform light source (such as a fluorescent lamp).

Capture details: Rotate the glass slightly to find wavy or striped patterns of alternating light and dark.

Tips for improving effectiveness:

Using polarized sunglasses or a polarizing film attached to a mobile phone for observation, the effect is more pronounced.

Compare and observe in different lighting environments (such as direct sunlight, indoor lighting) to improve accuracy.

Reminder:The visibility of Stress marks may be affected by glass thickness and production batch, and should be comprehensively judged in conjunction with other methods.

3、Edge Treatment Inspection: Quality Variations in Detail

Tempered glass must undergo mechanical precision grinding at its edges to ensure safety, which fundamentally differs from the manual cutting processes used for ordinary glass. By examining the edge treatment methods, one can assist in determining whether the glass is tempered.

| Comparison item | Tempered glass | ordinary glass |

|---|---|---|

| edge | Rounded edges with a smooth and fine texture, free of burrs and sharp edges. | Sharp-edged with potential residual sharp corners and coarse tactile texture. |

| Polish | Uniform edging with consistent grinding marks and no significant scratches or notches. | Rough edging with potential irregular notches or serrated edges. |

Applicable scenarios: This method is suitable for inspecting large glass products such as doors, windows, and glass partitions, especially for situations where stress spots cannot be directly observed.

4、Tapping and Sound Analysis: Experiential Sensory Judgment

Tempered glass exhibits distinct acoustic characteristics compared to annealed glass due to its internal stress distribution (surface compressive stress and interior tensile stress). While this method requires experiential judgment, it serves as a practical preliminary screening tool in non-laboratory settings.

Operation method:

Tap test: Tap the edge of the glass lightly with your knuckles, paying attention to the clarity and echo length of the sound.

Comparative judgment: Tempered glass typically produces a clear and sustained sound, and ordinary glass emits a dull and short-lived noise.

Limitations: Environmental noise, glass thickness, and other factors may interfere with the judgment. It is recommended to use it only as a preliminary screening method or in the presence of comparative samples.

5、Fragment morphology analysis: a detection method that can only be used for broken glass

This method is only applicable for posterior analysis of broken glass and should not be used for intact glass. By observing the shape of the broken fragments, it is possible to intuitively determine whether they are tempered glass.

Comparative features:

Tempered glass: broken into countless small particles, with passivated edges, resembling a honeycomb shape, without sharp edges, known as "safety glass".

Ordinary glass: After breaking, it forms large sharp fragments, which are highly dangerous.

Application scenario: This method is suitable for material determination at accident sites or for recycled glass, and does not require active use when making daily purchases.

6、 Practical advice: Safety guide for selection and use

Priority should be given to products with the 3C logo, and purchase vouchers should be retained for the purpose of safeguarding rights.It is recommended to entrust professional personnel to inspect the installation of large-sized glass to ensure compliance with safety standards.Avoid self-processing tempered glass, as breaking its stress balance can cause the entire piece to shatter.Regularly inspect old glass and replace parts with cracks or deformations in a timely manner.

The identification of tempered glass is not only related to product quality but also crucial for personal safety. By verifying 3C certification, observing stress patterns, inspecting edge treatments, tapping to listen for sound characteristics, and analyzing fragment morphology, consumers can scientifically assess glass materials. During selection and usage, maintaining vigilance and combining multiple methods for comprehensive judgment ensures true "safety without compromise." Professional evaluation always surpasses empirical assumptions – choosing qualified tempered glass demonstrates dual responsibility for both lifestyle quality and life safety.

Please visit product page for more information

-

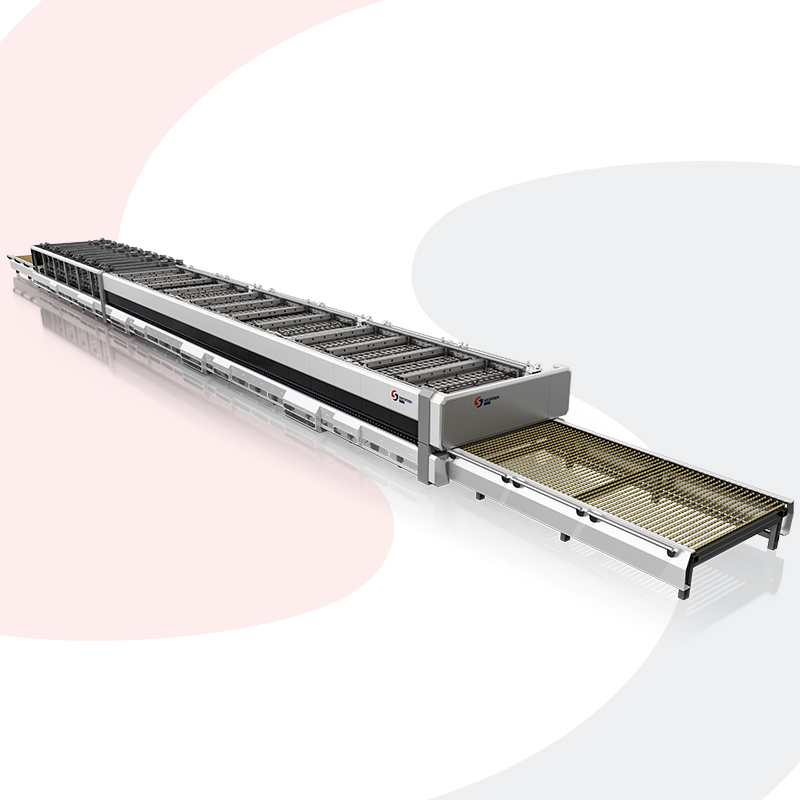

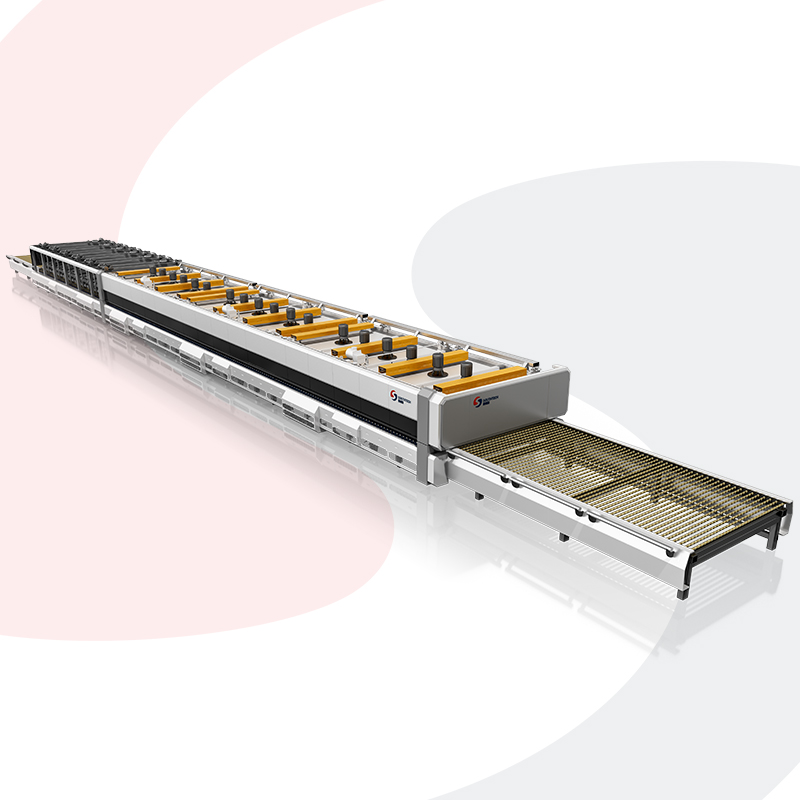

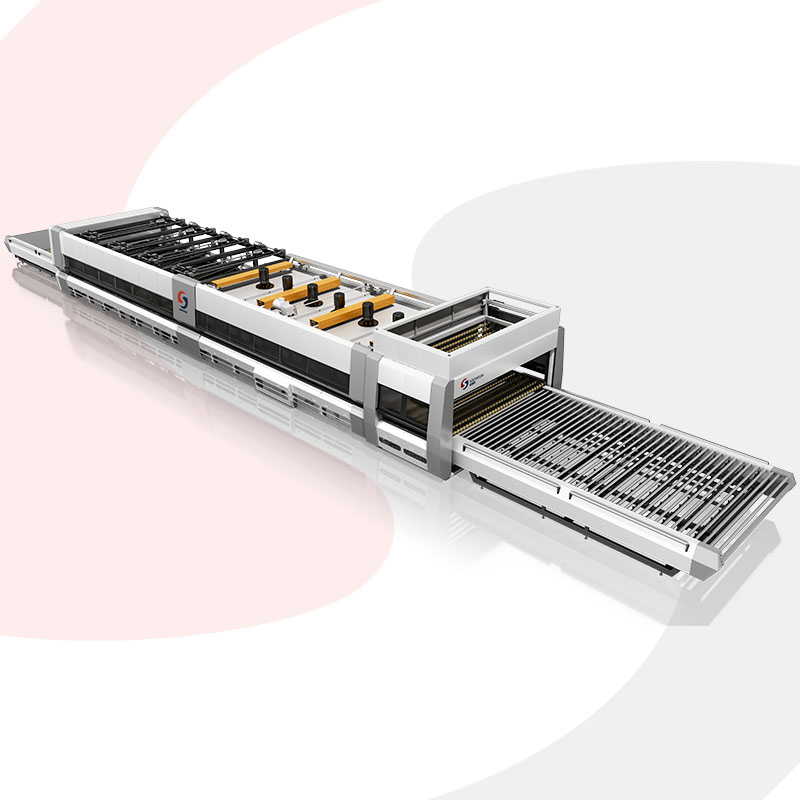

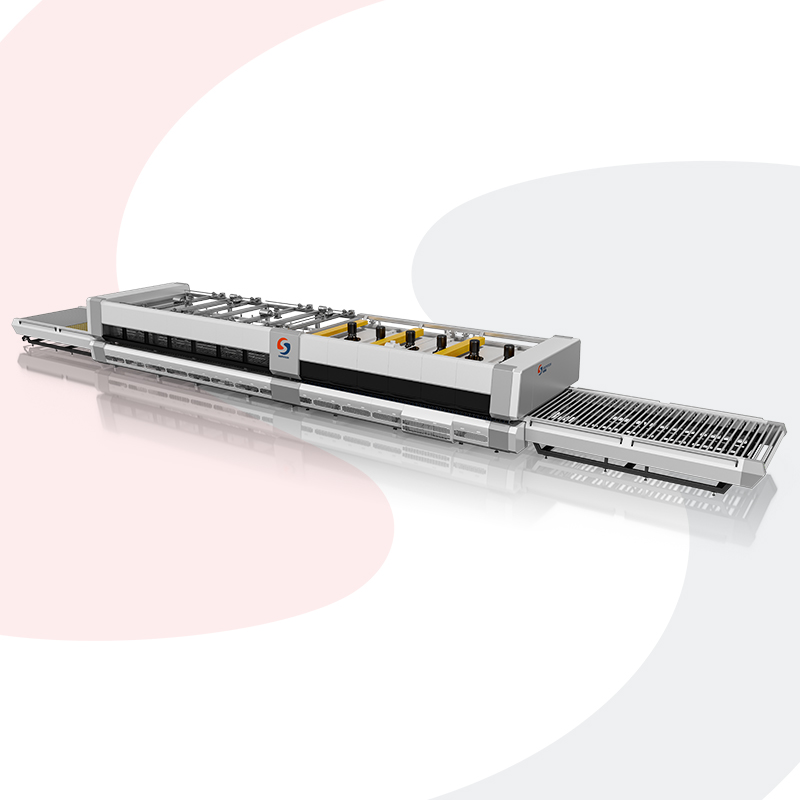

CONTINUOUS PASSING FLAT GLASS TEMPERING MACHINE

Category: Coated glass, Clear Float Glass, Tinted Glass, LOW-E Glass(Single, double and triple sliver), Ultra clear rolled glass, Full silk printing glass, silk printed border glass.

More

-

- Southtech Showcases at India’s glasspro Expo: Focusing on Customer Needs and Exploring Collaborations

- Practical Guide: How to scientifically distinguish tempered glass

- Southtech pioneers the "Horizontal Roller Hearth Tempering Furnace" group standard, setting a definitive industry benchmark.

- Glass Tempering Furnace: Science Popularization of Core Equipment for Safety Glass