Product recommendation

Southtech takes a leading role in compiling the group standard for "Horizontal roller hearth glass tempering furnace" For setting a new industry benchmark!

Recently, the group standard “Horizontal Roller Hearth Glass Tempering Furnace” (T/ZBH 030-2025), published by China Standards Publisher and officially released for implementation by the China Architectural and Industrial Glass Association, has come into effect. This not only fills the long-standing gap in China's glass tempering equipment sector where unified standards were lacking but also marks the industry's entry into a new era of high-quality development.

Behind this milestone standard, Southtech, as one of the core participating organizations, leveraged its profound technical expertise and forward-looking industry insights to play a key role in its development, contributing "Southtech wisdom" to the standardization and intelligent upgrading of the industry.

01 Filling the Gap, Setting the Benchmark

Tempered glass is widely used in construction, home appliances, photovoltaics, and other fields. As the core equipment for producing tempered glass, horizontal roller glass tempering furnaces directly affect product quality and the industry’s sustainable development through their performance, safety, and energy efficiency. For years, however, this glass machine sector suffered from inconsistent standards and a lack of authoritative technical guidelines, which has restricted the overall progress of the industry.

The official implementation of the standard has scientifically, systematically and comprehensively stipulated the core contents of the "Horizontal Roller Hearth Glass Tempering Furnace", including terms and definitions, classification, technical requirements (such as safety, transmission, heating section, cooling section, air supply system, control system, tempering capacity, energy consumption, production capacity, etc.), inspection methods, inspection rules, marking, packaging, transportation and storage.

This provides a definitive reference for designing, manufacturing, inspection, purchasing, and usage, effectively promoting technological upgrading, quality improvements, safety enhancements, and market standardization in the glass deep-processing machine industry. Its impact on ensuring tempered glass quality and advancing sustainable, high-quality development is significant and far-reaching.

02 In-Depth Participation: A Testament to Southtech’s Technical Strength

As a leading enterprise in the domestic field of intelligent equipment and technical solutions for glass deep processing, Southtech has always firmly believed that top-tier companies should not merely manufacture products, but also shape industry rules.

During the standard’s development, Southtech’s technical experts – drawing on over two decades of industry experience and practical data from thousands of installed units – actively contributed to discussions on technical clauses, offering numerous forward-thinking and actionable solutions. The company shared core R&D achievements in high-end tempering furnaces and engaged openly with industry experts to ensure the standard’s scientific rigor, applicability, and practicality.

From "standard executor" to "standard setter," Southtech is now guiding the industry’s direction with its technical influence.

03 Guided by Standards, Sustaining High-Quality Industry Development

Building on this participation, Southtech will continue to uphold the philosophy of "innovation-driven, quality-focused, and standard-led," and honor three key commitments:

1. Leading by example, exceeding standards

All Southtech furnaces will fully meet and surpass the new standard’s requirements, ensuring every unit leaving the factory delivers high stability, safety, and energy efficiency, truly achieving "benchmark-quality right off the production line."

2. Driving innovation, pioneering technology

Southtech will increase R&D investment to break new ground in intelligent control, performance optimization, ultra-low energy consumption, and enhanced tempered glass surface quality – creating smarter, more energy-efficient, and higher-performance next-generation tempering furnaces.

3. Deepening collaboration, building a shared ecosystem

The company will actively partner with industry associations, upstream/downstream enterprises, and research institutions to promote the standard’s adoption, foster collaborative innovation across the supply chain, and jointly build a standardized, healthy, and sustainable glass deep-processing ecosystem.

The Horizontal Roller Hearth Glass Tempering Furnace group standard represents a major milestone in the glass industry. Southtech takes great pride in contributing to this achievement – a responsibility that goes beyond honor. The company understands that true industry leadership means not just making excellent glass machines, but charting the path forward.

In the future, Southtech will continue to be guided by standards and driven by innovation, partnering with global collaborators to elevate China’s glass deep-processing machines to the world stage – and contributing the power of Chinese smart manufacturing to the green, intelligent development of global construction and industry.

Please visit product page for more information

-

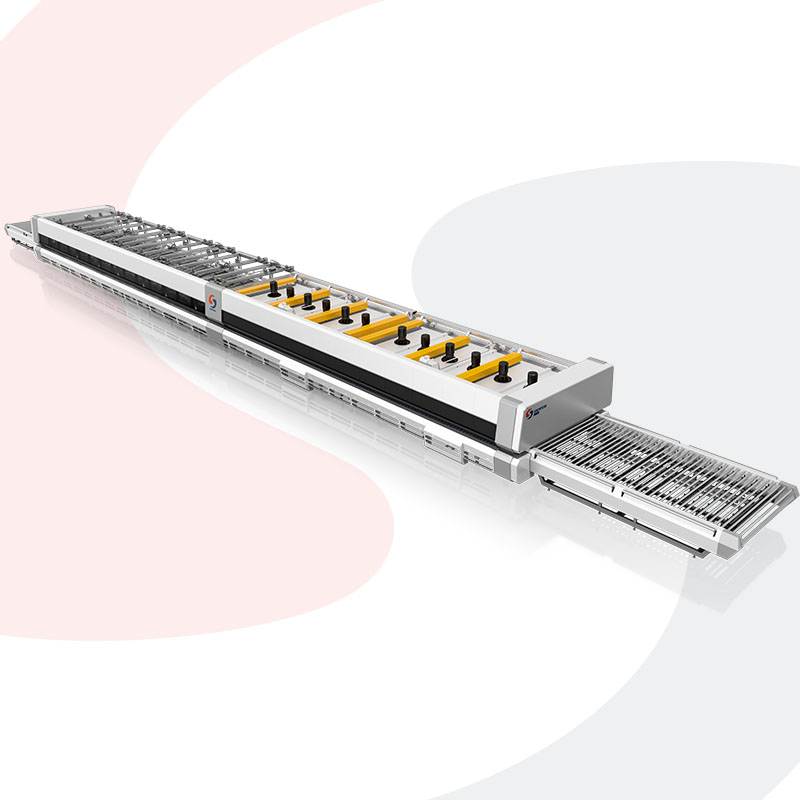

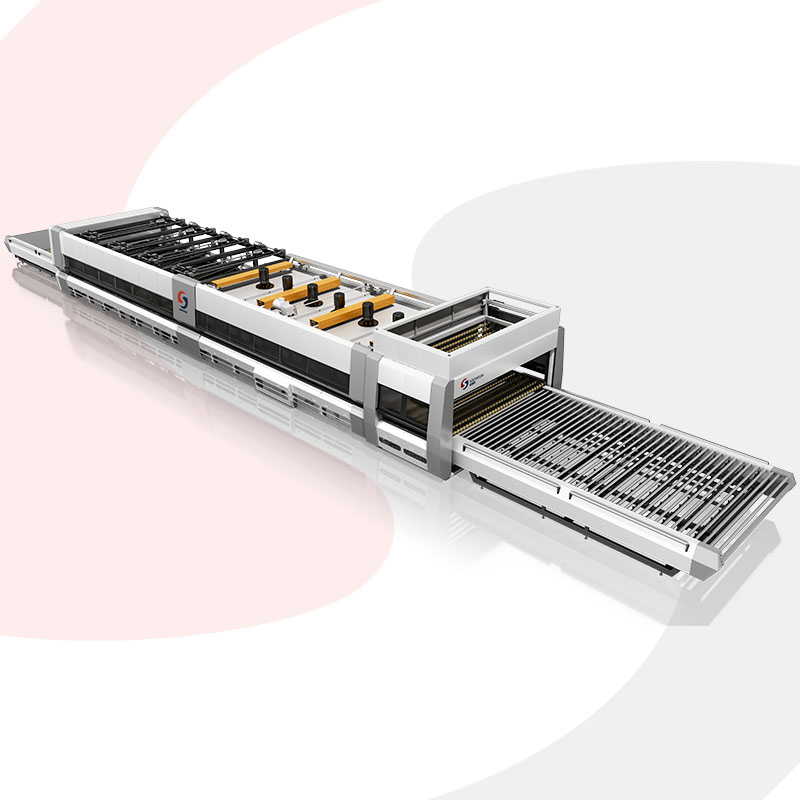

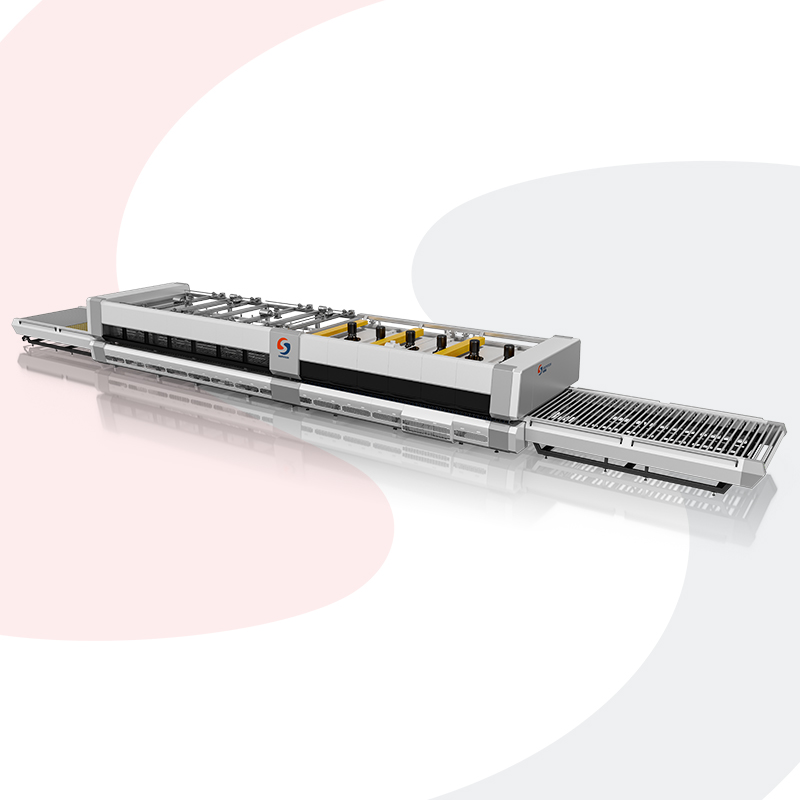

HIGH BOROSILICATE FLAMEPROOF GLASS TEMPERING FURNACE

Processed glass category: Coated glass, Clear Float Glass, Body Colored Float Glass, High Borosilicate 4.0 Glass, High Stress Glass.

More

-

- Southtech Showcases at India’s glasspro Expo: Focusing on Customer Needs and Exploring Collaborations

- Practical Guide: How to scientifically distinguish tempered glass

- Southtech pioneers the "Horizontal Roller Hearth Tempering Furnace" group standard, setting a definitive industry benchmark.

- Glass Tempering Furnace: Science Popularization of Core Equipment for Safety Glass